Geno,

I repeat:

Now that I looked at the gas valve, I'm convinced that you will in fact need a limit switch. Otherwise, if you use only time to move the dial CW and then later CCW, even if the two times are equal, the running friction of a reversible motor will not be equal running both directions, so you will always be accumulating positional error. You need a definite limit at least in one direction to re-index the position each cycle.

I have designed and simulated two different ways of doing it, but am out of time tonight to add details. You can look at this, but consider it unfinished...

Added Monday:

The circuit below is one way of driving a reversible DC gear motor. I'm assuming you want to push a button, the motor should run for a fixed time and then stop. When the button is pushed again, the motor runs for the same duration but in the opposite direction by causing the motor current to flow the other direction through the motor. Based on your motor specs I made the supply voltage 9V.

Since the button push must be "clean", I elected to use a momentary spring return type switch with three terminals, NC normally closed, NO normally open and C common. The Common is shown wired to 9V, and the NO and NC are wired to the SET and CLR inputs of a D Flip Flop. This "debounces" a flaky switch, to produce a clean clock signal for the second DFlop, which keeps track of the direction. Obviously, the circuit must be powered continuously for the DFlop to retain the information. The beauty of CMOS logic is that it draws very little power just sitting there powered. The funky Voltage sources V2 and V3 that control the switches are just the way this simulator models switches. The voltage source is just a convenient way of specifying when the switch is open and closed. Since I am modeling both the NO and NC sides of the switch it takes two of everything.

The second DFF is wired as a toggle, meaning it changes to the opposite of its current state every rising edge of the DB signal. The two outputs CW and CCW are capacitively coupled to the two 555 timers. It is the low going edge of the CW and CCW signals that trigger the 555 times alternatively. The 555s are wired as timers, meaning that when triggered, their output goes high for a time determined by the time constants R2C2 and R4C5, respectively. Since the other 555 is not triggered, its output is low, so current flows from the triggered 555, through the motor and into the 555 whose output is low, a poor man's H-Bridge

555s are rated to source and sink 200mA, so they should run your lightly loaded motor. If not, I have another circuit which will.

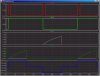

The plots from the simulation are attached. The top trace (Red) is the debounced button push, high when pushed, low when released. The second (green) trace is the direction flip-flop, showing how it changes direction every time the button is pushed. The next two traces (Gray and Dk Green) are from the RC timing networks in the two 555 timers, showing how they are triggered alternatively. The last trace is the current through the motor showing the three states: zero current when stopped, + current when running one way, - current when running the other.

To a first approximation, it does what you asked for, with one exception. I gave you the ability to adjust the CW running time independently from the CCW running time, because each 555 is independent of the other.

This is both a bad thing, and a good thing; bad because you will have to tweak the two periods, good because this way you stand a change of setting it up so that it travels the same distance both ways. If there was only one fixed period, I guarantee that you will accumulate positional error after each cycle.

As I was designing this, it occurred to me that you really shouldn't be using a push button but a toggle switch. The toggle switch intrinsically shows the position that the thermostat dial is set to. If you want to "turn it up", you can tell at a glance if it is "already Up", or if you need to move it to the other position. With a push button, there is nothing to tell you what position you are presently in (unless you add an indicator like a LED) which is driven off the Direction FlipFlop. Besides, the toggle switch greatly simplifies the circuit because you can eliminate both the debounce flop and the direction flop.

Now if I can convince you that you need limit switches to reindex it every cycle, you can eliminate the 555s, too.