marcbarker

New Member

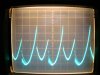

Yes I see what you mean now.

By my rough reckoning, @ 3 V = 5000 rpm

6 V = 10,000

9 V = 16,000

12 V = 19,000

Did by chance see of the RPM changed much with loading?

By my rough reckoning, @ 3 V = 5000 rpm

6 V = 10,000

9 V = 16,000

12 V = 19,000

Did by chance see of the RPM changed much with loading?