Leaffraun-N

New Member

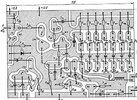

Hello, I would like to digitize and then manufacture such an old board, but I encountered a problem when choosing a program that could help me with this.

The thing is that this board (and three more auxiliary boards of this device) have non-standard curved pads for contacts.

Basically, I need to outline these pads with curved lines, and then make these curved perimeters solid (fill).

In tutorials on popular programs, I did not see anything similar to what I need. Because, in modern times, it is customary to distribute everything with ordinary angular buses.

But maybe there are other ways?

It's just... Unfortunately, I do not have enough experience in electronics to try to remake this (and other) boards in a modern way.

After all, these boards were designed by smart people, for a considerable current of a large number of transistors.

I would like to repeat exactly, for starters.

The thing is that this board (and three more auxiliary boards of this device) have non-standard curved pads for contacts.

Basically, I need to outline these pads with curved lines, and then make these curved perimeters solid (fill).

In tutorials on popular programs, I did not see anything similar to what I need. Because, in modern times, it is customary to distribute everything with ordinary angular buses.

But maybe there are other ways?

It's just... Unfortunately, I do not have enough experience in electronics to try to remake this (and other) boards in a modern way.

After all, these boards were designed by smart people, for a considerable current of a large number of transistors.

I would like to repeat exactly, for starters.