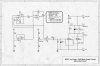

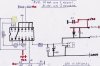

I found this site and saw specific solutions in diagram being exchanged. I am so close I can almost taste the diodes! Would some one please help me design the best circuit for my project...a diagram w/ part #s and some patience. I am a plumber in over my head and a week ago I didn't know spit. I simply need to control current without a huge drop in voltage. This is for an electrolysis project. The load simply being distilled water, anode and cathode and a current that will continually climb as the water takes on metallic particles and ions. Starting with a 30vdc source, I must keep the current between 2 and 8 mA's through out the process. SO, for this application, which would be better: 1. A sink, bipolar transistor, a resistor and 2 silicon diodes? 2. 2 NPN BJT'S and 4 resistors? 3. A voltage regulator (LM317), a N channel JFET and a resistor? 4. Or a fixed resistor in series with a variable resistor...which I would have to adjust constantly. Here is what is pertinent: I am trying to learn as fast as I can. However, I need the simple solution with the least amount of voltage drop. I guess "current limiting diodes" is a dying technology. I really need to get this done...my brain will have to catch up later. Part #'s, component values and descriptions is what I really need. If I cant specify values and ratings, I cant buy what I need. Even a example schematic of one of these circuits would help. So, I need mercy and help for now...but I do find this fascinating and plan on making it a hobby when I finish wrapping my brain around the theory,terminology and applications. Sorry for the long post.

plumber

plumber