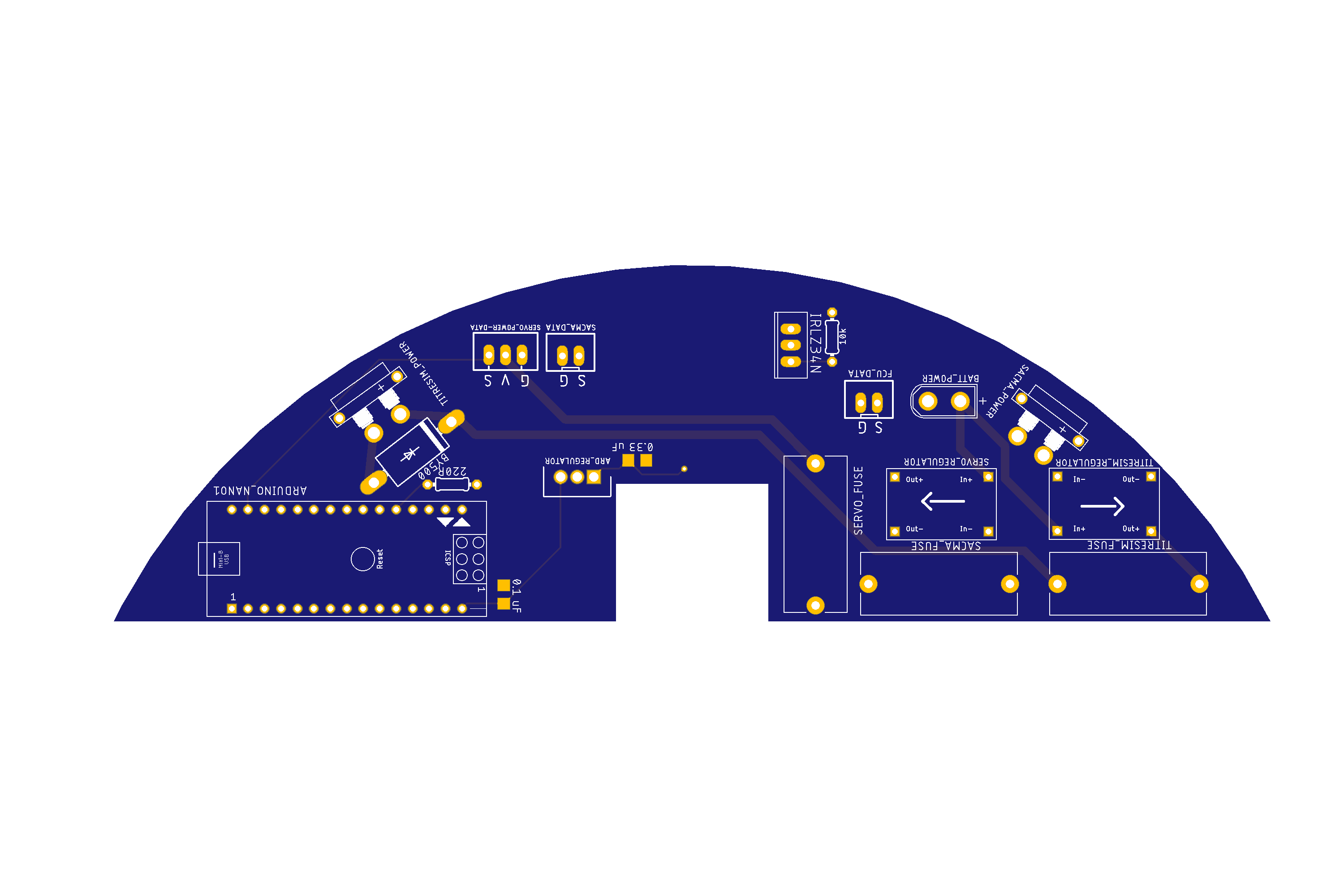

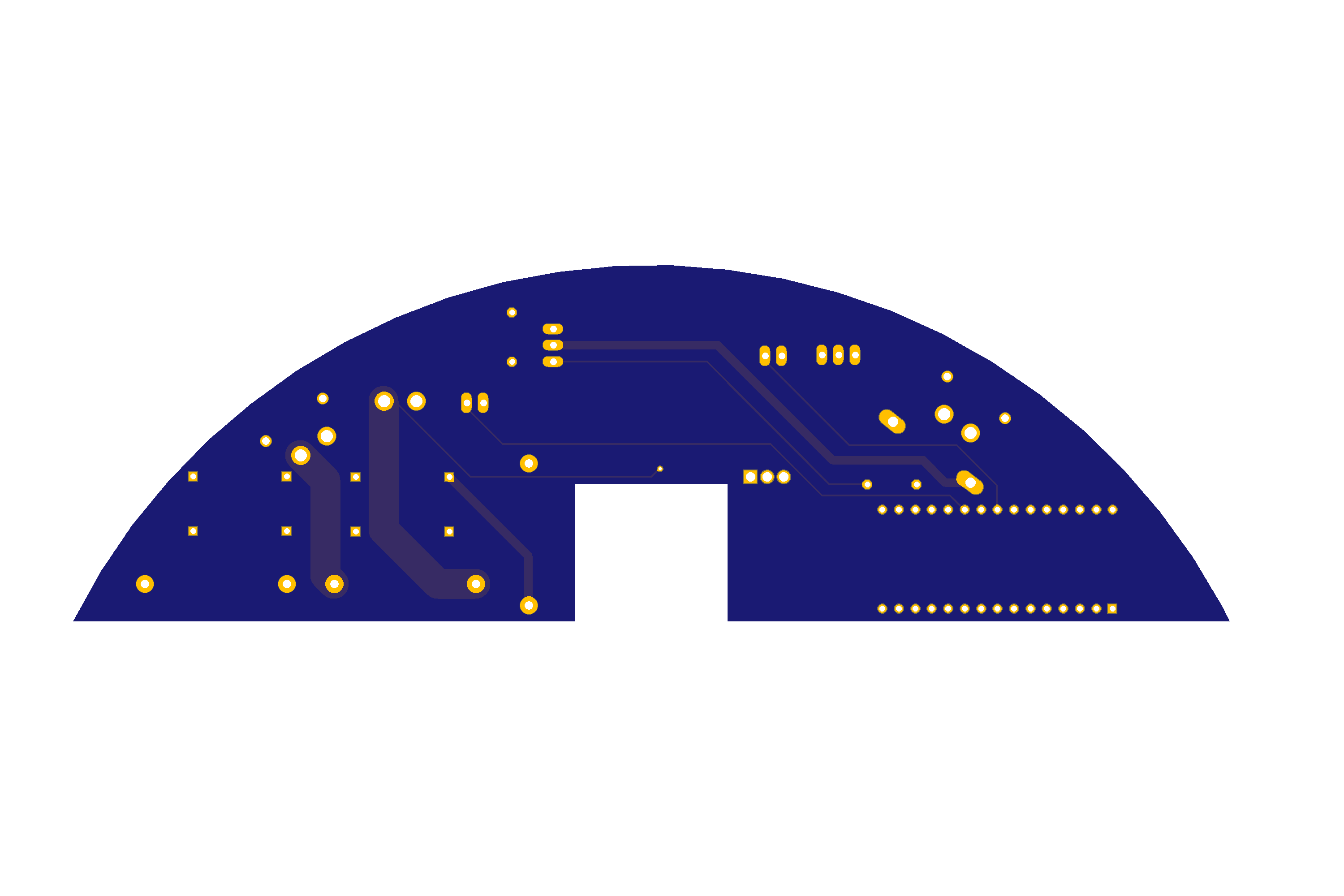

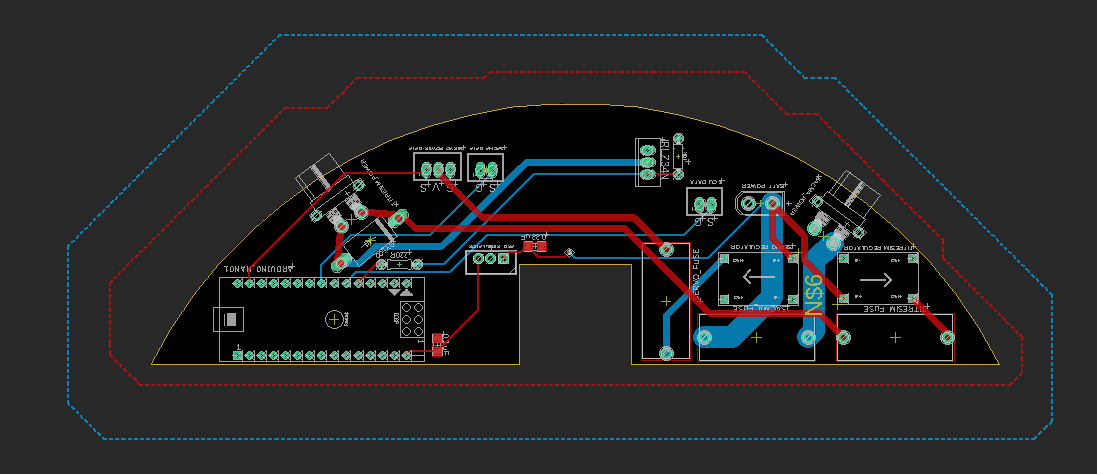

Hey, I needed to control a brushless motor(24V) with external ESC, Servo(5V), and brushed DC motor(9V) also I have a 6S battery. Then I designed a PCB. PCB has been received from the manufacturer. I tested it first I thought there was no problem but after 2-3 tries Arduino didn't operate the system properly. Servo, brushed motor and DC motor are opening and suddenly closing. Most of the time even they don't start. I can't upload code to Arduino when it is connected to PCB even PCB is unplugged from the battery. But when I disconnect the Arduino from PCB, Arduino is working well. Also, I can measure 0,5V from the main voltage line when PCB is unplugged from the battery. MOSFET side I am measuring -0,12V from +9V-drain when PCB is unplugged. I tried to attach the diode to the ESC power line but it didn't work. I will try to change MOSFET maybe I damaged the MOSFET. I think something wrong with the DC motor switching circuit. I need help. Thank you.

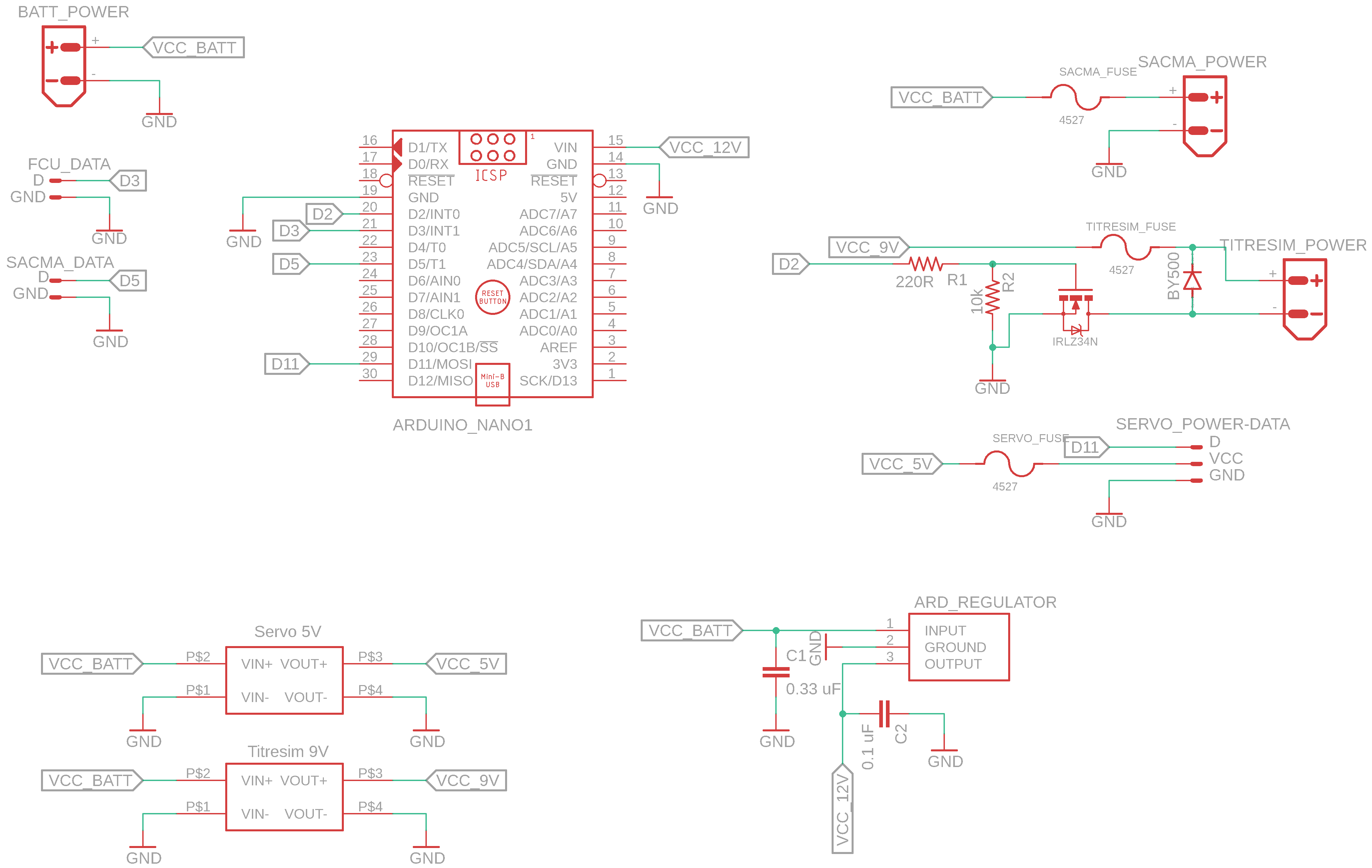

FCU_DATA: PWM data from Flight Controller Unit

Sacma_Power: ESC power line

Sacma_Data: ESC data line

Titresim_Power: DC motor power line

Ard_regulator: Arduino Voltage Regulator 24Vto12V L7812

Servo 5V: Servo's regulator MP1584 adjusted to 5V

Titresim 9V: DC motor's regulator MP1584 adjusted to 9V

VCC_Batt: 6S Battery

Brushless Motor: 6S 2A

Brushed DC Motor: 9V 2A

Servo:5V 2A

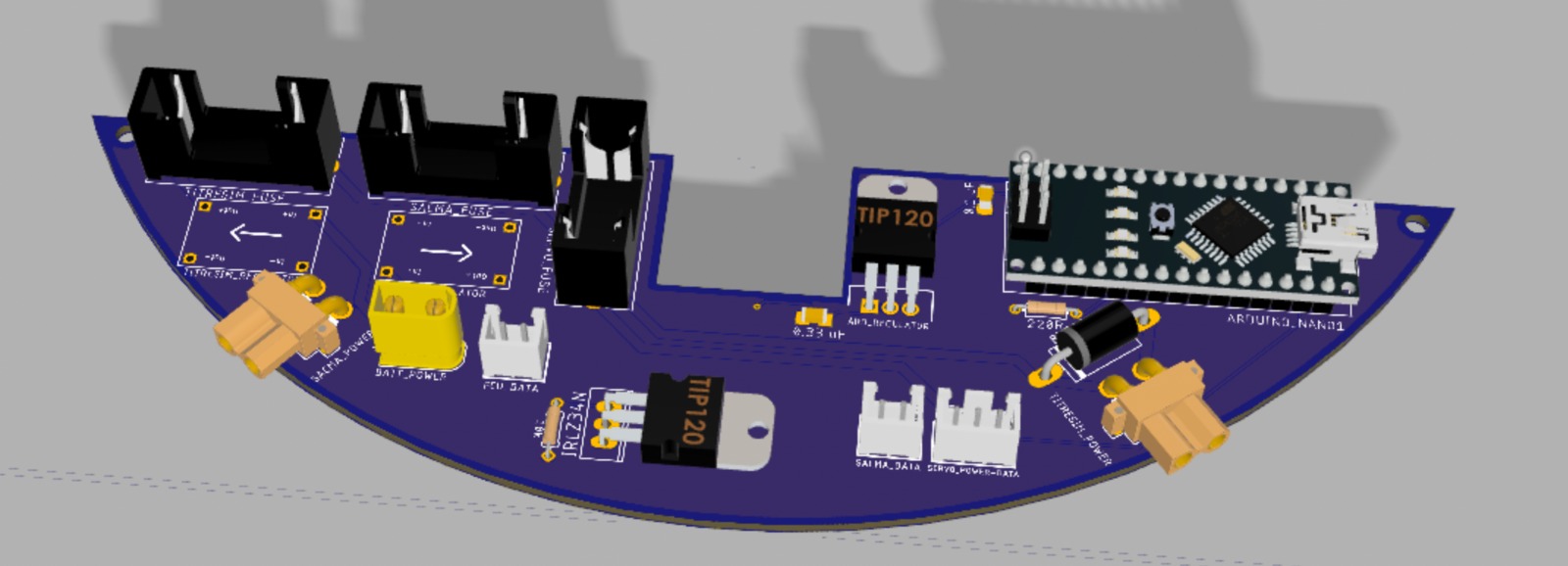

Ignore the 3D model's "TIP120" writing. Parts changed but I didn't change the 3D model.

View attachment 140759

View attachment 140759

FCU_DATA: PWM data from Flight Controller Unit

Sacma_Power: ESC power line

Sacma_Data: ESC data line

Titresim_Power: DC motor power line

Ard_regulator: Arduino Voltage Regulator 24Vto12V L7812

Servo 5V: Servo's regulator MP1584 adjusted to 5V

Titresim 9V: DC motor's regulator MP1584 adjusted to 9V

VCC_Batt: 6S Battery

Brushless Motor: 6S 2A

Brushed DC Motor: 9V 2A

Servo:5V 2A

Ignore the 3D model's "TIP120" writing. Parts changed but I didn't change the 3D model.