electrookie

New Member

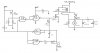

As I figured, I’m back again looking for help. This is a circuit I have been working on for several weeks or more and presented it previously with a different problem that was resolved by help from you in this forum. It has change to what is attached now and I am having other problems with it. If you can help me figure this out, it would be appreciated greatly, to say the least.

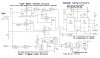

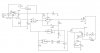

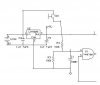

It is for controlling a pump. The idea is the pump is allowed to run for 3 to 5 seconds when the 1st clock of the 4528 is active (3 to 5 sec.). When the 1st clock times out, the 2nd clock starts and looks to see if Sw1 is still closed. (Sw1 is a float switch). If Sw1 is still closed, then the logic tells the fault relay to trip and it stays tripped till Sw3 is pressed to reset it. This prevents the pump from continuing to run and alerts there is a problem (light’s LED), typically with the float switch (I will probably end up using a latching relay, but that’s another issue).

The problem I am having is as follows: each section of the circuit works fine when separated from the rest. For some reason, when they are put together, the 2nd clock starts with the 1st clock & they run simultaneously. This defeats the purpose of the circuit. I have it built with the IC’s in sockets so I can lift individual pins to try to figure out what’s going on, but I am not getting anywhere. I have tried so many things and nothing is resolving these problems.

I made an analog AND gate in place of the U8a, that did basically the same thing, the same results. I just added the U8 IC and noticed that I can use one of its gates to replace what U6c & U6d are doing, but same difference, no matter how I lay it out, there are going to be excess gates, which is why I tried the analog AND gate.

I also noticed that the LED comes on when SW1 is activated, but the relay does not trip??? Apparently I am missing something when I combine these circuits. Can any of you spot the problem(s)? Any suggestions will be tried right away as I want to get this thing working and be done with it.

It is for controlling a pump. The idea is the pump is allowed to run for 3 to 5 seconds when the 1st clock of the 4528 is active (3 to 5 sec.). When the 1st clock times out, the 2nd clock starts and looks to see if Sw1 is still closed. (Sw1 is a float switch). If Sw1 is still closed, then the logic tells the fault relay to trip and it stays tripped till Sw3 is pressed to reset it. This prevents the pump from continuing to run and alerts there is a problem (light’s LED), typically with the float switch (I will probably end up using a latching relay, but that’s another issue).

The problem I am having is as follows: each section of the circuit works fine when separated from the rest. For some reason, when they are put together, the 2nd clock starts with the 1st clock & they run simultaneously. This defeats the purpose of the circuit. I have it built with the IC’s in sockets so I can lift individual pins to try to figure out what’s going on, but I am not getting anywhere. I have tried so many things and nothing is resolving these problems.

I made an analog AND gate in place of the U8a, that did basically the same thing, the same results. I just added the U8 IC and noticed that I can use one of its gates to replace what U6c & U6d are doing, but same difference, no matter how I lay it out, there are going to be excess gates, which is why I tried the analog AND gate.

I also noticed that the LED comes on when SW1 is activated, but the relay does not trip??? Apparently I am missing something when I combine these circuits. Can any of you spot the problem(s)? Any suggestions will be tried right away as I want to get this thing working and be done with it.