Hello!

I'm driving a 2006 Cadillac SRX that I recently purchased. it's growing on me, but one thing that bugs me is Cadillac made the front amber turn signals do double duty as daytime running lamps (DRL). by double duty, there's only one circuit into the bulb and the flasher drives that circuit as either +12 V for DRL's, or alternating +12/0 V for turn signals (like normal). My goals:

1. I like amber turn signals but I'd really like white DRL's (like all the newer cars and the bright LED's)

2. North Carolina actually allows white turn signals but what fun is the trival solution?

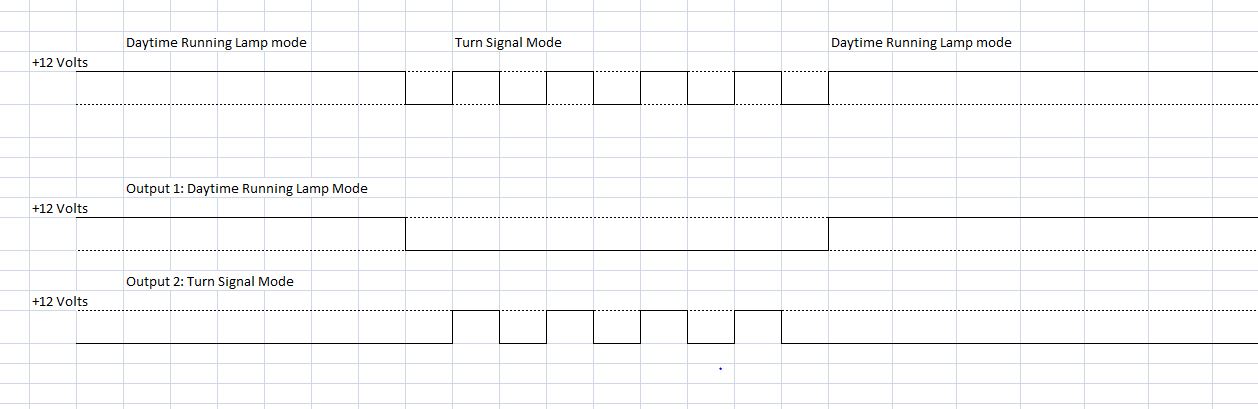

I've purchased replacement LED bulbs called switchbacks that have amber LED's on one circuit and white LED's on a 2nd circuit. but they don't work because the car doesnt' have two separate circuits. So to make those work I need to split the signal like this:

schematically, it looks like this:

One point to bear in mind...the GM bulb socket wasn't fully populated ( 2 pins, 1 blank) but the aftermarket replacement parts are fully populated with three pins. so adding one more wire isn't impossible.

thanks for your time, I'm looking forward to your creative solutions!!

I'm driving a 2006 Cadillac SRX that I recently purchased. it's growing on me, but one thing that bugs me is Cadillac made the front amber turn signals do double duty as daytime running lamps (DRL). by double duty, there's only one circuit into the bulb and the flasher drives that circuit as either +12 V for DRL's, or alternating +12/0 V for turn signals (like normal). My goals:

1. I like amber turn signals but I'd really like white DRL's (like all the newer cars and the bright LED's)

2. North Carolina actually allows white turn signals but what fun is the trival solution?

I've purchased replacement LED bulbs called switchbacks that have amber LED's on one circuit and white LED's on a 2nd circuit. but they don't work because the car doesnt' have two separate circuits. So to make those work I need to split the signal like this:

schematically, it looks like this:

One point to bear in mind...the GM bulb socket wasn't fully populated ( 2 pins, 1 blank) but the aftermarket replacement parts are fully populated with three pins. so adding one more wire isn't impossible.

thanks for your time, I'm looking forward to your creative solutions!!