Hello circuit gurus.

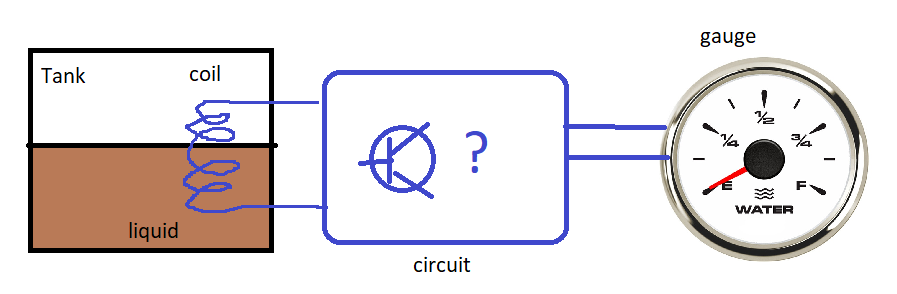

I am trying to come up with a simple circuit design for the induction based meter of the liquid level in the tank.

The idea is simple:

- on the input side, a coil is placed in the tank,

- in the output side is a gauge, showing the liquid's level.

As the liquid level in the tank fluctuates, the submerged portion of the coil will change, affecting its impedance, which will be reflected by the gauge.

I am thinking of two possible principles:

1). Coil based oscillator - its frequency changes with the liquid level, and the gauge indicates the frequency

2). Fixed frequency alternating current passes through the coil, its impedance changes with the level change, and gauge indicates the current flowing through the coil

Other sensor types were considered: open contact, float, capacitive, optical/IR, sonar, etc., but they cannot be used because it is a moving dirty liquid (sewage) tank on the boat, and whatever sensors are placed there will become clogged/obstructed, as the dirty liquid splashes and dries over the sensors.

Obviously, the circuit will have to be calibrated and adding a loose ferrous floater inside the coil is an option.

Any help (ideas, circuit drawings, etc.) will be appreciated.

Thank you in advance.

Captain Alex

I am trying to come up with a simple circuit design for the induction based meter of the liquid level in the tank.

The idea is simple:

- on the input side, a coil is placed in the tank,

- in the output side is a gauge, showing the liquid's level.

As the liquid level in the tank fluctuates, the submerged portion of the coil will change, affecting its impedance, which will be reflected by the gauge.

I am thinking of two possible principles:

1). Coil based oscillator - its frequency changes with the liquid level, and the gauge indicates the frequency

2). Fixed frequency alternating current passes through the coil, its impedance changes with the level change, and gauge indicates the current flowing through the coil

Other sensor types were considered: open contact, float, capacitive, optical/IR, sonar, etc., but they cannot be used because it is a moving dirty liquid (sewage) tank on the boat, and whatever sensors are placed there will become clogged/obstructed, as the dirty liquid splashes and dries over the sensors.

Obviously, the circuit will have to be calibrated and adding a loose ferrous floater inside the coil is an option.

Any help (ideas, circuit drawings, etc.) will be appreciated.

Thank you in advance.

Captain Alex