Fluffyboii

Active Member

Hi,

I am working on a tesla coil and this is the most pricy and time consuming project of my life. I discovered how hard to build a resonating transformer in a hard way.

Actually I am kinda happy with my setup. I got more then 10 cm sparks. But thats not enough.

Secondary: 910 turns, diameter 7cm, length 47cm. 24awg 200 meters wire used.

Primary made from 4 meters of fridge pipe 6 turns ideal resonance for now

I made a huge foil capacitor after exploding different homemade ones. The single capacitor is 16 nano farads. Before I roll it It was 1 nano farads but It increased alot (I knew It will increase but not that much)

I use a flyback with a ZVS driver and a modified M.O.T. It consumes 3.5 Amps at 10 volts But I can't measure it with 55 volts because its to much for my multimeter.

Spark gap can be widen at 3 cm when working with 55 volts but at 30 volts max length is 2cm.

My flyback primary wires are thin because of the spacing problem and wire gets over 90 degrees if I use it at 55 volts for too long. I tried to put flyback in oil but it leaked so I give up.

The problem is I saw people geting way better results with lower voltage at ZVS drivers and less power. And everyone seems like using at least 10 turns on primary. And I don't have a proper ground connection in my house. I got long sparks jumping to primary coil from my secondary. I put a pipe around the secondary to prevent that But because the lack of a ground connection it some how happens. I tryed to lower the primary for better coupling but that didn't help too.

I wonder If I lower the capacitor value and increase the turn number to achive resonance, can that increase performance by increasing the magnetic flux. Or It will be the same. The 16nf capacitor is my only working capacitor and I don't want to cut it for lowering the capacitance and probably my flyback isn't able to charge that fully until the spark gap fires. But the copper tubing isn't cheap :/

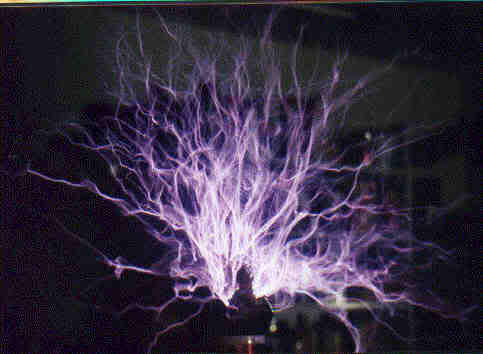

It feels like I am doing something wrong. You can see my early test picture, The new output is better than that. I don't have to much photos But I can take more if needed. I didn't find any usefull information on my mother language

Sorry for bad English. I am writing on a phone and because of that I can't check for spelling or grammar mistakes. I hope this will not melt your eyes.

I am working on a tesla coil and this is the most pricy and time consuming project of my life. I discovered how hard to build a resonating transformer in a hard way.

Actually I am kinda happy with my setup. I got more then 10 cm sparks. But thats not enough.

Secondary: 910 turns, diameter 7cm, length 47cm. 24awg 200 meters wire used.

Primary made from 4 meters of fridge pipe 6 turns ideal resonance for now

I made a huge foil capacitor after exploding different homemade ones. The single capacitor is 16 nano farads. Before I roll it It was 1 nano farads but It increased alot (I knew It will increase but not that much)

I use a flyback with a ZVS driver and a modified M.O.T. It consumes 3.5 Amps at 10 volts But I can't measure it with 55 volts because its to much for my multimeter.

Spark gap can be widen at 3 cm when working with 55 volts but at 30 volts max length is 2cm.

My flyback primary wires are thin because of the spacing problem and wire gets over 90 degrees if I use it at 55 volts for too long. I tried to put flyback in oil but it leaked so I give up.

The problem is I saw people geting way better results with lower voltage at ZVS drivers and less power. And everyone seems like using at least 10 turns on primary. And I don't have a proper ground connection in my house. I got long sparks jumping to primary coil from my secondary. I put a pipe around the secondary to prevent that But because the lack of a ground connection it some how happens. I tryed to lower the primary for better coupling but that didn't help too.

I wonder If I lower the capacitor value and increase the turn number to achive resonance, can that increase performance by increasing the magnetic flux. Or It will be the same. The 16nf capacitor is my only working capacitor and I don't want to cut it for lowering the capacitance and probably my flyback isn't able to charge that fully until the spark gap fires. But the copper tubing isn't cheap :/

It feels like I am doing something wrong. You can see my early test picture, The new output is better than that. I don't have to much photos But I can take more if needed. I didn't find any usefull information on my mother language

Sorry for bad English. I am writing on a phone and because of that I can't check for spelling or grammar mistakes. I hope this will not melt your eyes.

Attachments

-

E8E43B43-A8DB-43CE-B4D8-52BE354D2EE3.jpeg976.6 KB · Views: 689

E8E43B43-A8DB-43CE-B4D8-52BE354D2EE3.jpeg976.6 KB · Views: 689 -

CFA8CF81-7C8A-4A10-BF62-5FD9FFBEFBBD.jpeg1.2 MB · Views: 528

CFA8CF81-7C8A-4A10-BF62-5FD9FFBEFBBD.jpeg1.2 MB · Views: 528 -

12197862-FBC7-44A7-BCD3-4C7130FEB1D3.jpeg115.5 KB · Views: 547

12197862-FBC7-44A7-BCD3-4C7130FEB1D3.jpeg115.5 KB · Views: 547 -

9B748727-9433-4F99-9BF1-0FDBFCFD5CD1.jpeg173.9 KB · Views: 591

9B748727-9433-4F99-9BF1-0FDBFCFD5CD1.jpeg173.9 KB · Views: 591 -

FCA47582-C3F8-47F5-904C-9373DE56ACED.jpeg181.6 KB · Views: 552

FCA47582-C3F8-47F5-904C-9373DE56ACED.jpeg181.6 KB · Views: 552 -

CF5EEC52-ADFF-4FCF-9C6A-939CFA67F577.png287.8 KB · Views: 536

CF5EEC52-ADFF-4FCF-9C6A-939CFA67F577.png287.8 KB · Views: 536