dinofx

New Member

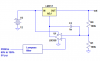

I'm going to use PWM to control the feedback pin to an LM317. I need to vary output voltage from 6 to 10 linearly based on duty cycle, so the control pin voltage needs to range roughly from 5 to 9 volts.

So, I have a square wave between 0 and +5 volts. I need the square wave boosted to +5 and +9 (let's say). I'm going to run the output through an RC filter to get a stable signal between 5 and 9 volts, which will then feed into the control pin.

I have a 12VDC power supply for the entire circuit.

Can this be done with on 741, some resistors and possible a pair of diodes? Thanks for your ideas.

So, I have a square wave between 0 and +5 volts. I need the square wave boosted to +5 and +9 (let's say). I'm going to run the output through an RC filter to get a stable signal between 5 and 9 volts, which will then feed into the control pin.

I have a 12VDC power supply for the entire circuit.

Can this be done with on 741, some resistors and possible a pair of diodes? Thanks for your ideas.