I was thinking of this:

https://hubbellcdn.com/specsheet/WIRING_HBL5278C_spec.pdf, but it isn't.

There was a connector that I purchased from newark.com, probably Hubbell that was basically a flange mount twist lock. The wierd thing about the specification was 125/250, but it was grounding.

This

https://www.mcmaster.com/6755K222/ comes close mounting wise, but it's not grounding.

Here

https://www.mcmaster.com/6755K172/ is the grounded version. The one I used was dual marked like the one above.

I needed a locking power connector because power came from wall mounted outlets in an array of surface mounted raceways.

The equipment was about 15-20' away but we had both 120 and 208 stuff. Guess what, either variacs or temperature controllers. If you removed a piece of equipment to work on it, you used a shorter power cord. It was too difficult to undo.

Since they were built by me, it was possible to convert to 120/240 relatively easy. Maybe I used 240 style breakers, but only connected 1/2 of them for the variacs. Heat tape. application.

For the temperature controllers which needed a "positive disconnect", I would include a 120V relay and a transformer with a 120/208 primary to 120V secondary and two fuseholders where one would not be used.

One or two separate over temperature units would disconnect the power via the contactor. This, was the only system that required over temperature protection of this magnitude. One type would actually mount in the back of the case. The rack was open, so no big deal.

The controllers I built also offered off on power glitch or not depending on the application. That was front panel set.

The internal wiring change wasn't just one jumper, but because I liked to make appliances, I designed it in. When/if the reactor was de-commishioned the parts would still be viable.

I made tabletop temperature control boxes that were there 28 years later. newer controllers were a little longer than the box.

The front panel had a real 30A disconnect. On/Off and Int/Ext 0-5 setpoint in. ON/OFF allowed you to see the temperature when turned off. The disconnect allowed the output to be potential free.

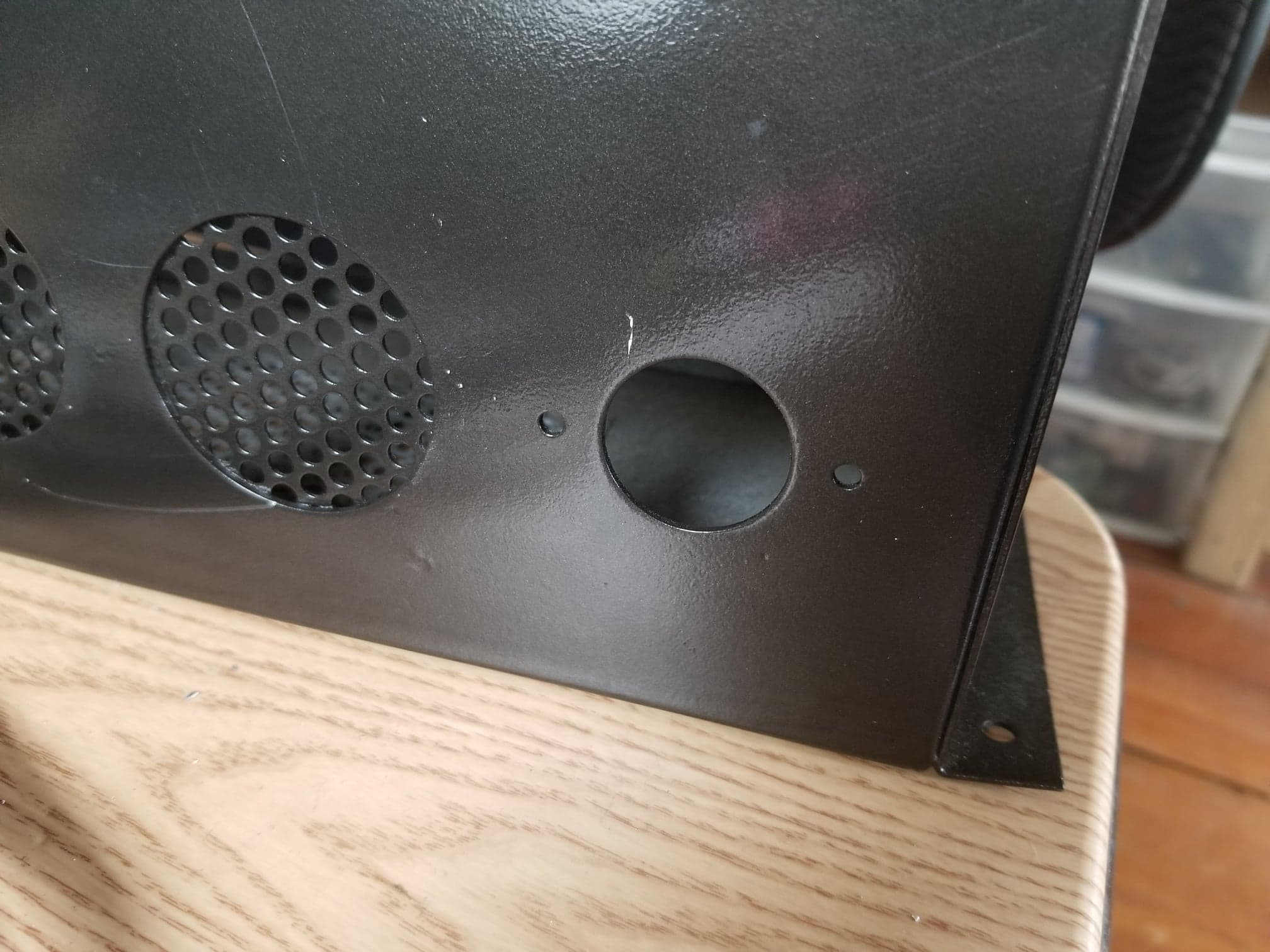

The rear panel had a panel mounted TC input AND a grommet for a extension wire pigtail.

Setpoint in, Measured value was available on a screw terminal strip. Chart recorder stuff when used for manual tuning.

There was a locking current limit potentiometer.

I don't remember what I did for power in/power out, but I think I had cable and receptacles for out and cable for in.

Controllers were 1/4 DIN. Some newer 1/8 DIN controllers were put into the same box.