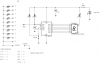

I need a Cable Core Identifier to establish the phase rotation in an un-energised three phase H.V. Cable. prior to jointing. My thoughts were by using three coloured LEDs to confirm correct connection.

I recall seeing a circuit back in the 80's - 90's where three LED's were used in a transmitter that had three leads that connected to the cable at one end and a reciever was connected to the other end by three leads. The leads were swapped until all LED's were lit.

All that I can find on the internet is a instrument that is already built and for sale, but not a circuit.

Can anybody help with the design of a circuit.

Regards

I recall seeing a circuit back in the 80's - 90's where three LED's were used in a transmitter that had three leads that connected to the cable at one end and a reciever was connected to the other end by three leads. The leads were swapped until all LED's were lit.

All that I can find on the internet is a instrument that is already built and for sale, but not a circuit.

Can anybody help with the design of a circuit.

Regards