Hi,

I'm relatively new to the forums, first post here, but I've been trolling through looking to see if I find an answer before posting. Sorry if this happens to be a redundant posting.

Here's the scenario:

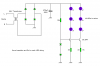

I'm looking to design a UV Exposure unit for PCB/Silk Screening using LEDs. I know the basics of what I want for power and LEDs. Based on my calculations I need 48Vdc for the LEDs including a 100Ω resistor for each series array.

While I've been reading a lot about power supply design, I'm wondering if it's even worth attempting to build my own power supply, or look for an off the shelf regulated power supply that will give the 48V I'm needing. (At least, I'm thinking I'm needing a regulated power supply.)

I figured I'd give this question first before inundating the forum with questions pertaining to building a power supply if it would be wiser/cheaper to purchase something pre-made. Granted I'd like to learn more about building a supply, but I'm still learning the intricacies based on what I've been reading.

I'm also looking to figure out a way to make the individual series arrays essentially modular so if one array flakes out, the entire unit doesn't have to be sent in for servicing. Unplug the faulty module, and replace it with a new one. The problem I'm running into is finding a solution like a buss system that is readily available without having to manufacture it by hand.

Any suggestions would be appreciated. Any links to information gladly accepted.

I'm relatively new to the forums, first post here, but I've been trolling through looking to see if I find an answer before posting. Sorry if this happens to be a redundant posting.

Here's the scenario:

I'm looking to design a UV Exposure unit for PCB/Silk Screening using LEDs. I know the basics of what I want for power and LEDs. Based on my calculations I need 48Vdc for the LEDs including a 100Ω resistor for each series array.

While I've been reading a lot about power supply design, I'm wondering if it's even worth attempting to build my own power supply, or look for an off the shelf regulated power supply that will give the 48V I'm needing. (At least, I'm thinking I'm needing a regulated power supply.)

I figured I'd give this question first before inundating the forum with questions pertaining to building a power supply if it would be wiser/cheaper to purchase something pre-made. Granted I'd like to learn more about building a supply, but I'm still learning the intricacies based on what I've been reading.

I'm also looking to figure out a way to make the individual series arrays essentially modular so if one array flakes out, the entire unit doesn't have to be sent in for servicing. Unplug the faulty module, and replace it with a new one. The problem I'm running into is finding a solution like a buss system that is readily available without having to manufacture it by hand.

Any suggestions would be appreciated. Any links to information gladly accepted.