AtlasRucker84

New Member

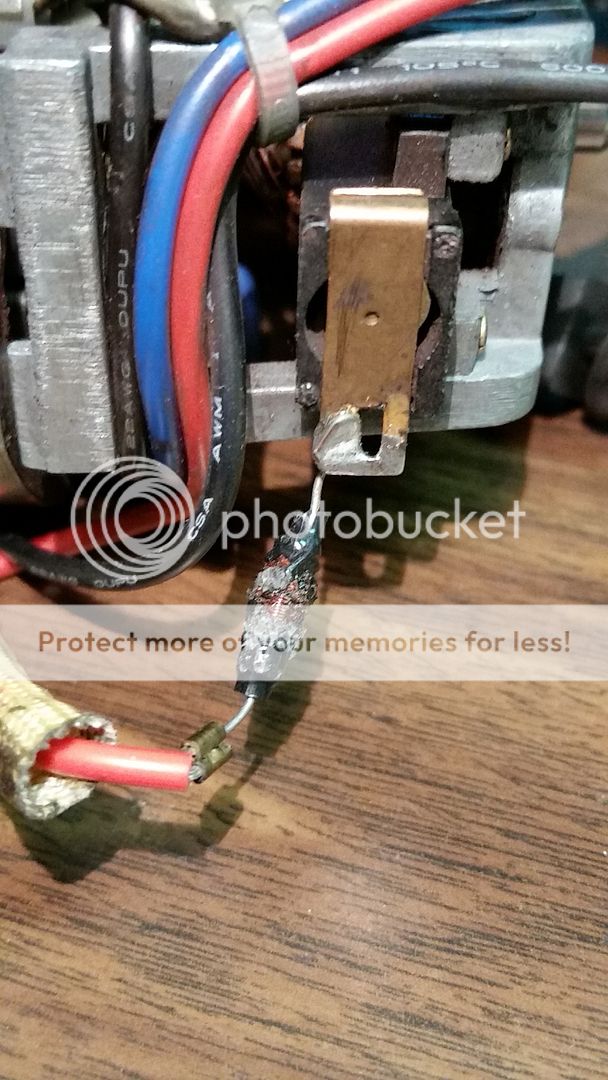

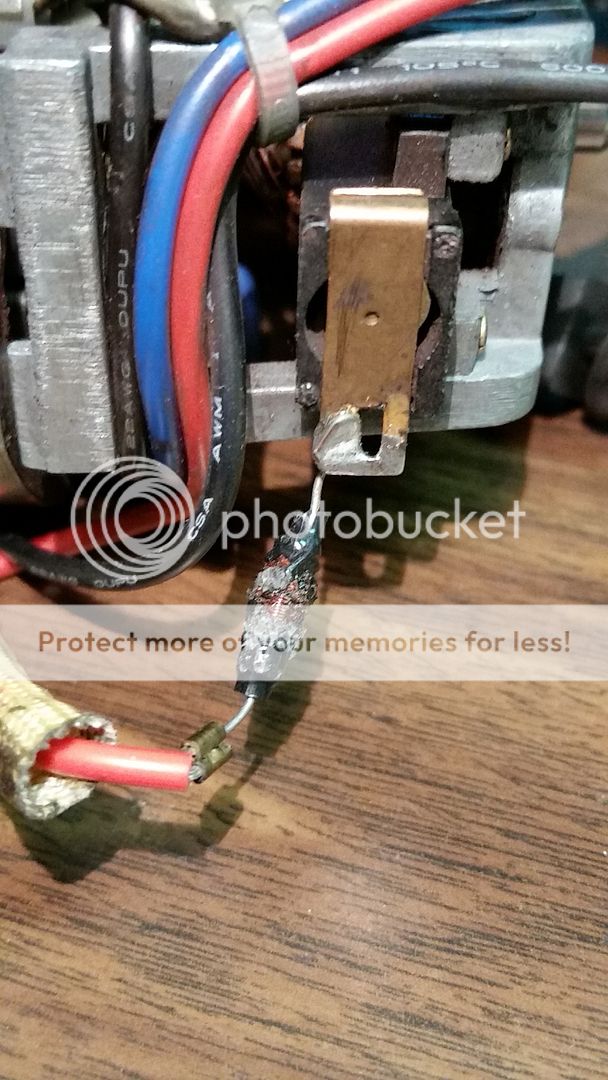

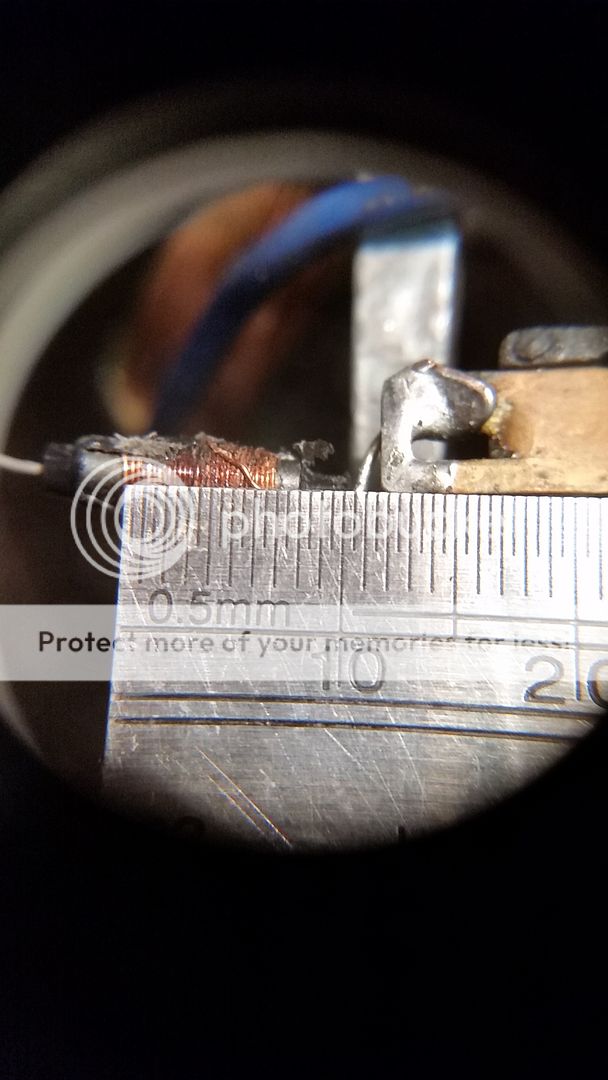

I need help with this. I am not educated in electronics, but know enough to get by with basic repairs or etc. So the other day I burned up something that probably is not worth my time fixing, but I figured, hey might be something simple, a thermal fuse on the motor windings. I knew it was going to be more then a common fuse, as it had that distinctive odor to it. So I get into it and rip the whole damn thing apart. So I get the guts of the thing and the motor windings and circuit board are intact, presumably. Then I look at the back of the motor and off the electrical bushing there are two components in series on both the positive and neutral sides. Sure enough they were burnt to a crisp. The only problem is I have no idea what they are or what the ratings would be for replacements. From what I can gather they are axial RF choke inductors. Which is in itself is puzzling to me. Why not capacitors or resistor capacitor combo? Why use a RF inductor opposed to some other EMI noise reduction, assuming that's what they're for?

Some info:

12v axial shaft high torque motor

Inductors???:

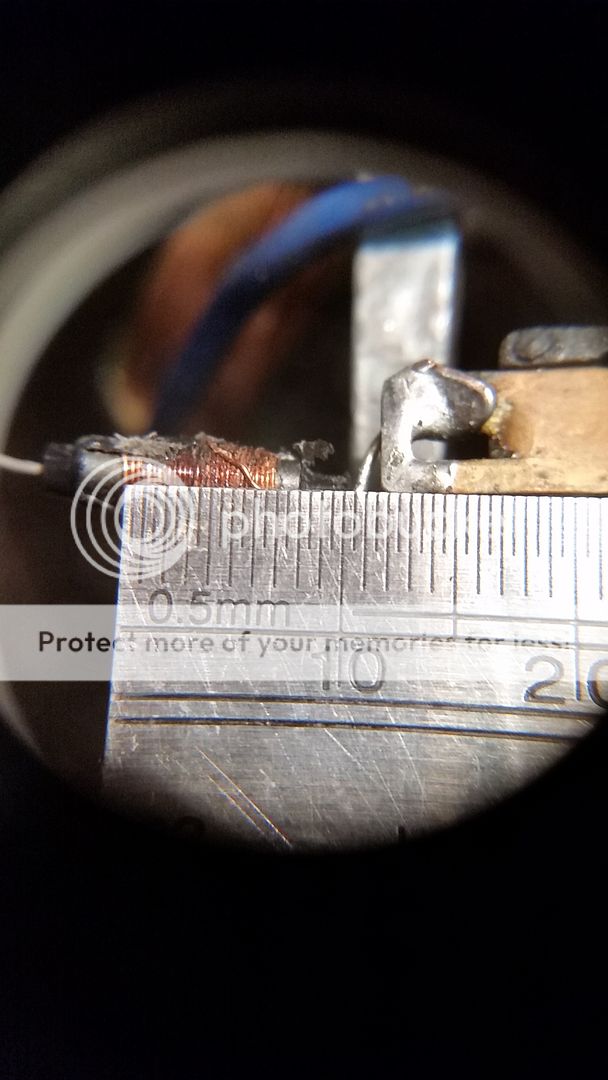

4 turn per mm

28 turns on the bottom

10 turns on top layer

3mm Dia. ferrite rod core by 10.15mm in length

0.30 mm (according to my digital gauge) so roughly 29 Gauge copper turnings.

Some info:

12v axial shaft high torque motor

Inductors???:

4 turn per mm

28 turns on the bottom

10 turns on top layer

3mm Dia. ferrite rod core by 10.15mm in length

0.30 mm (according to my digital gauge) so roughly 29 Gauge copper turnings.