I'm designing a fixture that takes a DC input from a power supply and essentially just passes it through to another device. Essentially it consists of a breaker and a switch.

I want to build in an indicator circuit to light an LED when the input voltage is within 10% of the required 28VDC.

I wanted to use a FET, but we do not have any in stock that will work with my voltage levels, so my next best thing is a BJT.

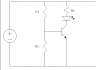

My thought was to use a voltage divider set up so that Vbe would be 0.6V when my Vin is roughly 25V. Then I have the LED on the collector with a current limiting resistor. See my attached diagram please.

I've done my homework, but I'm not sure if I fully understand the operation of the BJT. I haven't done this since school...

For R1 I've calculated 330ohms, R2 a 4.7 and 3.3 to get 8ohms. R3 is 1.2kohms to limit my LED current to roughly 20mA. My voltage divider is set up to provide .6V across R2 and Vbe @ 25.35VDC in. Have I done this right? Do I control base current with the collector current, or is it the other way around? I want my Ib to be ~2mA.

If it helps, it is a 2V LED. Specs on the transistor are Vcesat=.3V, Vbesat=.6-1.2V.

Not looking for an answer, just helpful hints. Maybe a little push in the right direction.

I want to build in an indicator circuit to light an LED when the input voltage is within 10% of the required 28VDC.

I wanted to use a FET, but we do not have any in stock that will work with my voltage levels, so my next best thing is a BJT.

My thought was to use a voltage divider set up so that Vbe would be 0.6V when my Vin is roughly 25V. Then I have the LED on the collector with a current limiting resistor. See my attached diagram please.

I've done my homework, but I'm not sure if I fully understand the operation of the BJT. I haven't done this since school...

For R1 I've calculated 330ohms, R2 a 4.7 and 3.3 to get 8ohms. R3 is 1.2kohms to limit my LED current to roughly 20mA. My voltage divider is set up to provide .6V across R2 and Vbe @ 25.35VDC in. Have I done this right? Do I control base current with the collector current, or is it the other way around? I want my Ib to be ~2mA.

If it helps, it is a 2V LED. Specs on the transistor are Vcesat=.3V, Vbesat=.6-1.2V.

Not looking for an answer, just helpful hints. Maybe a little push in the right direction.

Attachments

Last edited: