Help please

I have a very low power out put from a tractor lift sensor. +12v up & 0v down. I need to be able to operate a switch from this to enable the sat nav to know whether the lift is up or down. But the switch must only be open or closed, i.e. no voltage. The obvious answer is a relay but the 12v is very low amperage. I have try all sorts of relays, solid state and coil but they all drain too much power and don't work. The only thing that the 12V will power is a led.

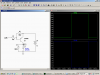

Is it possible to use a simple transistor circuit to overcome this or any other ideas appreciated.

I have a very low power out put from a tractor lift sensor. +12v up & 0v down. I need to be able to operate a switch from this to enable the sat nav to know whether the lift is up or down. But the switch must only be open or closed, i.e. no voltage. The obvious answer is a relay but the 12v is very low amperage. I have try all sorts of relays, solid state and coil but they all drain too much power and don't work. The only thing that the 12V will power is a led.

Is it possible to use a simple transistor circuit to overcome this or any other ideas appreciated.