Hi,

I want to turn on a fan(AC/220V/50H) using IR obstacle Sensor/NPN(NO) Output as the follwing:

1-)While the sensor seeing the object the fan will be on.

2-)If the object passes the sensor the Fan will be on for a certain time varies from (5 Min - 20 Min).

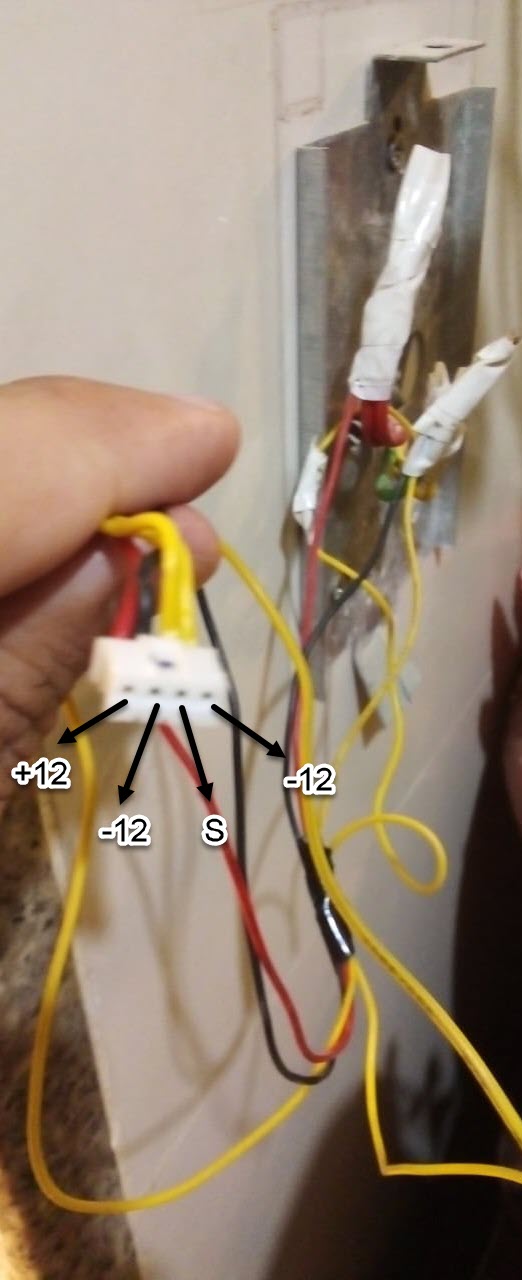

the following Figure show the available wires for me (+12v,-12v,S,-12v)

S: Sensor output(when it see any object the output become -12v)

could anyone help me to design the circuit to do what i need ?

Regards.

I want to turn on a fan(AC/220V/50H) using IR obstacle Sensor/NPN(NO) Output as the follwing:

1-)While the sensor seeing the object the fan will be on.

2-)If the object passes the sensor the Fan will be on for a certain time varies from (5 Min - 20 Min).

the following Figure show the available wires for me (+12v,-12v,S,-12v)

S: Sensor output(when it see any object the output become -12v)

could anyone help me to design the circuit to do what i need ?

Regards.