bigal_scorpio

Active Member

Hi again to all,

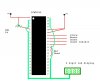

A quick explanation, I'm trying to make a tachometer for my sons lathe with the ICM 7225 counter/display driver.

The LED part of the circuit was no problem and works fine coming on fully lit then counting.

Since I don't understand the data sheet which seems lacking in the usual info, although the sheet says one use of the chip is a tachometer I can't figure out how.

Since experimenting, connecting pin 34 (store) to +V starts the chip counting but, I don't know what its counting and this is with out pin 32 (count) even connected. No where on the data sheet is there a mention of the IC having an internal pulse for it to count!

My pulse would be coming from a spinning disc on the lathe shaft breaking the signal through an opto device. I have inserted a picture of my circuit and the data sheet below, so if you can help me please, please, please do so, I am wracking my brains and already down to less hairs than Homer Simpson.

Thanks for reading this............Al

A quick explanation, I'm trying to make a tachometer for my sons lathe with the ICM 7225 counter/display driver.

The LED part of the circuit was no problem and works fine coming on fully lit then counting.

Since I don't understand the data sheet which seems lacking in the usual info, although the sheet says one use of the chip is a tachometer I can't figure out how.

Since experimenting, connecting pin 34 (store) to +V starts the chip counting but, I don't know what its counting and this is with out pin 32 (count) even connected. No where on the data sheet is there a mention of the IC having an internal pulse for it to count!

My pulse would be coming from a spinning disc on the lathe shaft breaking the signal through an opto device. I have inserted a picture of my circuit and the data sheet below, so if you can help me please, please, please do so, I am wracking my brains and already down to less hairs than Homer Simpson.

Thanks for reading this............Al

Attachments

Last edited: