Hi everyone

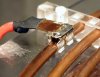

i am building a 1.8KW tesla tower and i have a problem

i couldn't make the primery part round because the wire was too strong,

plus my HV Hawg capacitor is 21.6 nF instead of 21.2 nF ,,

does that effect my design and will it work ?

thanks in advance for your help

**broken link removed**

i am building a 1.8KW tesla tower and i have a problem

i couldn't make the primery part round because the wire was too strong,

plus my HV Hawg capacitor is 21.6 nF instead of 21.2 nF ,,

does that effect my design and will it work ?

thanks in advance for your help

**broken link removed**