Hi there, I have just joined this forum to ask for help. I have searched the forums already but unfortunately I have not found anything that is of any help to myself.

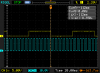

I have just carried out an engine conversion on a project car and am trying to convert a 12v 4 pulse per revolution signal to a 12v 64 pulse per revolution signal. Therefore I am looking to make or buy, depending on the difficulty, a 12v 16x signal multiplier so that my tachometer reads correctly.

There are a fair few tachometer signal converters on the market however the most they go to is 10x multiplication and these tend to be quite expensive. I greatly appreciate any help you guys can give me.

Thanks Dan

ClarkAE

I have just carried out an engine conversion on a project car and am trying to convert a 12v 4 pulse per revolution signal to a 12v 64 pulse per revolution signal. Therefore I am looking to make or buy, depending on the difficulty, a 12v 16x signal multiplier so that my tachometer reads correctly.

There are a fair few tachometer signal converters on the market however the most they go to is 10x multiplication and these tend to be quite expensive. I greatly appreciate any help you guys can give me.

Thanks Dan

ClarkAE