Just wanted to share this with the uC guys here.

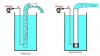

We were talking about airlifts on another forum. A suction dredge is used to remove silt from rives and harbors works on this principle.

The one wekipedia talked about works by releasing a bubble into a 4 inch pipe 10 or more feet long. Air is injected into the bottom of the tube for 1 to 3 seconds forming an air bubble. When the air bubble reaches the top of the pipe the next bubble is generated.

I was thinking what a fun uC project. Generating the timing for the bubble and controlling the duration of the bubble should be standard fare.

The fun part comes with detecting when the bubble reaches the top. This is not guaranteed to be a constant especially during start up. One could use probes at the top of the pipe to detect the lack of an electrical path. But it would be a lot more fun to play with the PIC CTMU to notice the capacitance change when the bubble passes by.

It would be a blast to set this up and play with bubble size and bubble release times based on where the previous bubble was.

Am I going to do it? I already have too many irons in the fire but it is tempting.

We were talking about airlifts on another forum. A suction dredge is used to remove silt from rives and harbors works on this principle.

The one wekipedia talked about works by releasing a bubble into a 4 inch pipe 10 or more feet long. Air is injected into the bottom of the tube for 1 to 3 seconds forming an air bubble. When the air bubble reaches the top of the pipe the next bubble is generated.

I was thinking what a fun uC project. Generating the timing for the bubble and controlling the duration of the bubble should be standard fare.

The fun part comes with detecting when the bubble reaches the top. This is not guaranteed to be a constant especially during start up. One could use probes at the top of the pipe to detect the lack of an electrical path. But it would be a lot more fun to play with the PIC CTMU to notice the capacitance change when the bubble passes by.

It would be a blast to set this up and play with bubble size and bubble release times based on where the previous bubble was.

Am I going to do it? I already have too many irons in the fire but it is tempting.