Gasboss775

Member

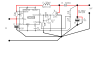

I built the attached step up circuit using an mc34063 and an external IRL2910 N Ch MOSFET. With the component values shown the mc34063 operated at nearly 200 KHz and the output was around 10 volts, with a 100ohm load instead of the design figure of 15 Volts.

This operating frequency is way above that stated in the data sheet. Is there any reason why it would do this with the external switch rather than the in built one.

Note it was an ONsemiconductor mc34063.

This operating frequency is way above that stated in the data sheet. Is there any reason why it would do this with the external switch rather than the in built one.

Note it was an ONsemiconductor mc34063.