Hi,

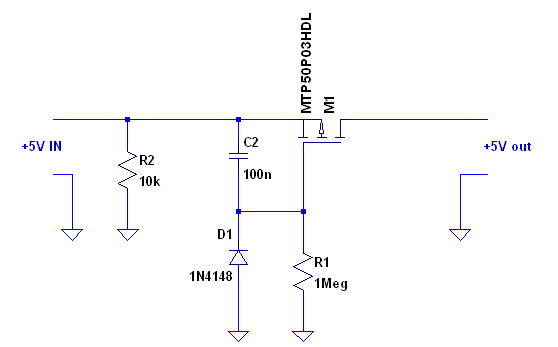

I'm testing a soft start circuit which is posted here earlier: (having SI4465DY in place of M1)

I'm having problems with the inrush current of 5V step-up converter ordered from Pololu.com, which is only drawing huge amounts of current and is unable to start properly because of Vin dropping too much in this situation. I'm building a Geiger dosimeter which will be powered by 2 AA NiMH cells, which means Vin to be no more than 2.4V when they are nearly empty, and will drop more when taking current from them. Even with my power supply it's a little shaky to start properly, unless I give it at least 3 volts. I wanted to use 4 AA cells which would help a lot, but couldn't find any enclosure with 4 AA compartment suitable for this project so I have to live with 2 cells.

With that soft-start circuit I'm able to start my project having Vin as low as 2.2V (the step-up converter is in the left side of that picture), but there's still an another problem. D1 and R2 are meant to rapidly discharge C2 so the soft start is immediately ready to work again and it works, however any capacitors in the device itself (in the right side of that picture) will leak back thru the body diode of M1 and therefore the soft-start is not "reloaded" before those other caps are also discharged. That can take up to several seconds. In the event of main power switch contact bouncing, it's very possible that the step-up converter will again go nuts because C2 didn't have time to discharge, and will blow the fuse or something else.

Anyone having ideas how to get the C2 rapidly discharged when putting power off, regardless of other caps there? Putting a diode after M1 is no-go because of too much voltage loss. My project will use up to 50 mA of current, but typically only 15 - 25 mA.

I'm testing a soft start circuit which is posted here earlier: (having SI4465DY in place of M1)

I'm having problems with the inrush current of 5V step-up converter ordered from Pololu.com, which is only drawing huge amounts of current and is unable to start properly because of Vin dropping too much in this situation. I'm building a Geiger dosimeter which will be powered by 2 AA NiMH cells, which means Vin to be no more than 2.4V when they are nearly empty, and will drop more when taking current from them. Even with my power supply it's a little shaky to start properly, unless I give it at least 3 volts. I wanted to use 4 AA cells which would help a lot, but couldn't find any enclosure with 4 AA compartment suitable for this project so I have to live with 2 cells.

With that soft-start circuit I'm able to start my project having Vin as low as 2.2V (the step-up converter is in the left side of that picture), but there's still an another problem. D1 and R2 are meant to rapidly discharge C2 so the soft start is immediately ready to work again and it works, however any capacitors in the device itself (in the right side of that picture) will leak back thru the body diode of M1 and therefore the soft-start is not "reloaded" before those other caps are also discharged. That can take up to several seconds. In the event of main power switch contact bouncing, it's very possible that the step-up converter will again go nuts because C2 didn't have time to discharge, and will blow the fuse or something else.

Anyone having ideas how to get the C2 rapidly discharged when putting power off, regardless of other caps there? Putting a diode after M1 is no-go because of too much voltage loss. My project will use up to 50 mA of current, but typically only 15 - 25 mA.