Hey Guys,

I found this forum searching for answers regarding the design of H-bridge circuits for DC motor control.

I've hit a snag with my design (which is my 1st ever), and in my reading I've found that many of you seem to have much experience with DC motor controls. Any help would be much appreciated!

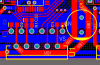

I have developed a board with the purpose of controlling the current applied to three Maxon F2260 motors (889 winding), link to datasheet below

https://irtfweb.ifa.hawaii.edu/~tcs3/tcs3/vendor_info/Maxon/F2260%20Motor.pdf

The main performance criteria for my controller is to apply smooth ripple free current to the motor. The motor is coupled to a robot that a user interacts with by backdriving the robot.. and I want the motor to have no feeling besides the intended torque signal.

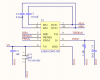

Im using dsPIC33f microcontrollers to drive each of the three axis.. and have the PWM set to 20KHz. These each in-turn are connected to LMD18200T H-Bridge drivers.

I've noticed two things in this design.. not sure if this is typical or not

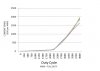

1) That I have a huge deadband for PWM, where I assumed the voltage (or current) across my motor would be linear with the duty cycle. I did a graph of the motor current as a function of my PWM duty cycle.. you will see several lines representing my testing at different shaft angles, and for each of my 3 motors.

(image attached)

So for my controller I've had to fit an equation to this data such that I can somewhat accurately command current to my motor.

2) The continuous current rating for my motor is 1.69 amps, which is well below the 3A continuous rating for H-bridge driver. At about half of this current value.. around 0.8A the motor begins to feel gritty when you backdrive the shaft... This is highly undesirable for my design.. since the whole point of my robot is to transmit smooth torque through the robotic linkage to a human hand.

I tried hooking up my oscilloscope over the motor terminals to see what the actual signal was doing... and this ended up actually changing the performance of my circuit.. and something didnt seem right.. so I pulled the scope of in fear that I might damage it..

anyways.. this post is getting long.. any help would be much appreciated..

cheers,

I found this forum searching for answers regarding the design of H-bridge circuits for DC motor control.

I've hit a snag with my design (which is my 1st ever), and in my reading I've found that many of you seem to have much experience with DC motor controls. Any help would be much appreciated!

I have developed a board with the purpose of controlling the current applied to three Maxon F2260 motors (889 winding), link to datasheet below

https://irtfweb.ifa.hawaii.edu/~tcs3/tcs3/vendor_info/Maxon/F2260%20Motor.pdf

The main performance criteria for my controller is to apply smooth ripple free current to the motor. The motor is coupled to a robot that a user interacts with by backdriving the robot.. and I want the motor to have no feeling besides the intended torque signal.

Im using dsPIC33f microcontrollers to drive each of the three axis.. and have the PWM set to 20KHz. These each in-turn are connected to LMD18200T H-Bridge drivers.

I've noticed two things in this design.. not sure if this is typical or not

1) That I have a huge deadband for PWM, where I assumed the voltage (or current) across my motor would be linear with the duty cycle. I did a graph of the motor current as a function of my PWM duty cycle.. you will see several lines representing my testing at different shaft angles, and for each of my 3 motors.

(image attached)

So for my controller I've had to fit an equation to this data such that I can somewhat accurately command current to my motor.

2) The continuous current rating for my motor is 1.69 amps, which is well below the 3A continuous rating for H-bridge driver. At about half of this current value.. around 0.8A the motor begins to feel gritty when you backdrive the shaft... This is highly undesirable for my design.. since the whole point of my robot is to transmit smooth torque through the robotic linkage to a human hand.

I tried hooking up my oscilloscope over the motor terminals to see what the actual signal was doing... and this ended up actually changing the performance of my circuit.. and something didnt seem right.. so I pulled the scope of in fear that I might damage it..

anyways.. this post is getting long.. any help would be much appreciated..

cheers,