I have a small DC inverter arc welder (https://www.decaweld.com/default.asp?cmd=getProd&cmdID=19306) that has an annoying problem I'd like to fix. One day after using the machine I noticed that the switch was stuck in the "on" position. Not thinking much of it, I replaced the switch. The first time I powered it on again, I saw a significant arc in the new power switch, which was now also welded in the "on" position. I have used the machine since out of necessity, just plugging/unplugging it from the wall to power on/off. When doing this, an arc occurs between plug and receptacle. While I have an incredibly basic knowledge of electronics and am comfortable replacing components, diagnosing this problem is well beyond my capabilities. I am hoping that someone with more skill and knowledge than myself can offer some assistance.

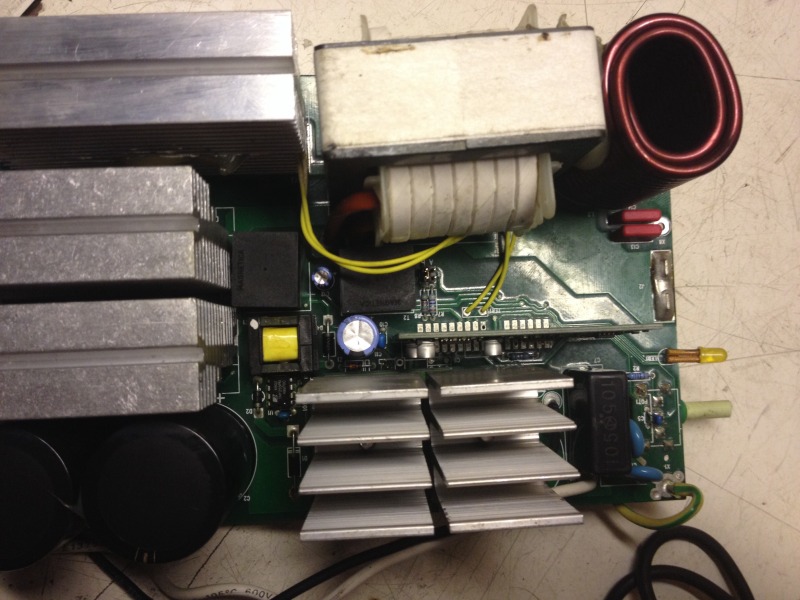

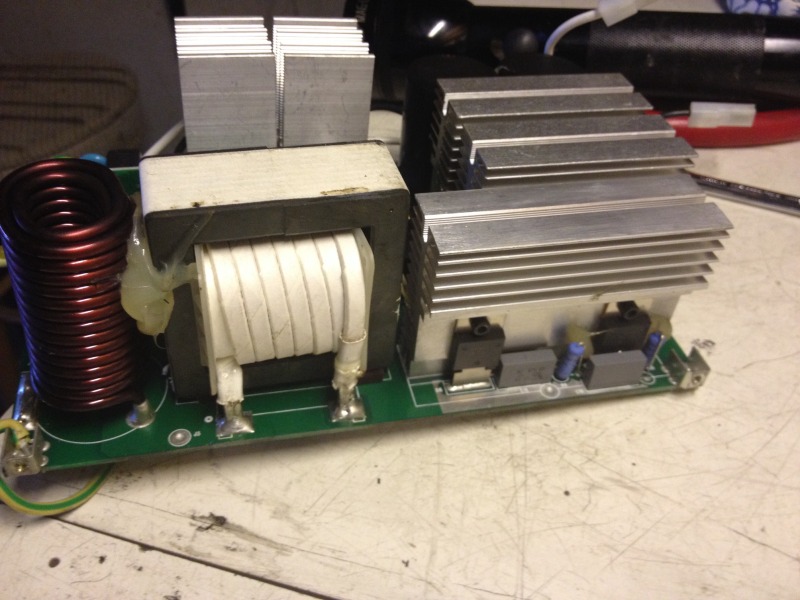

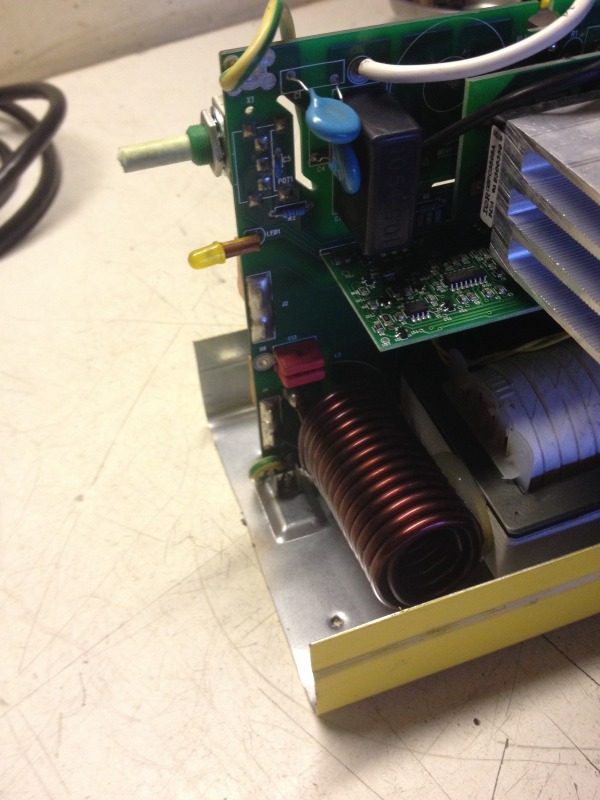

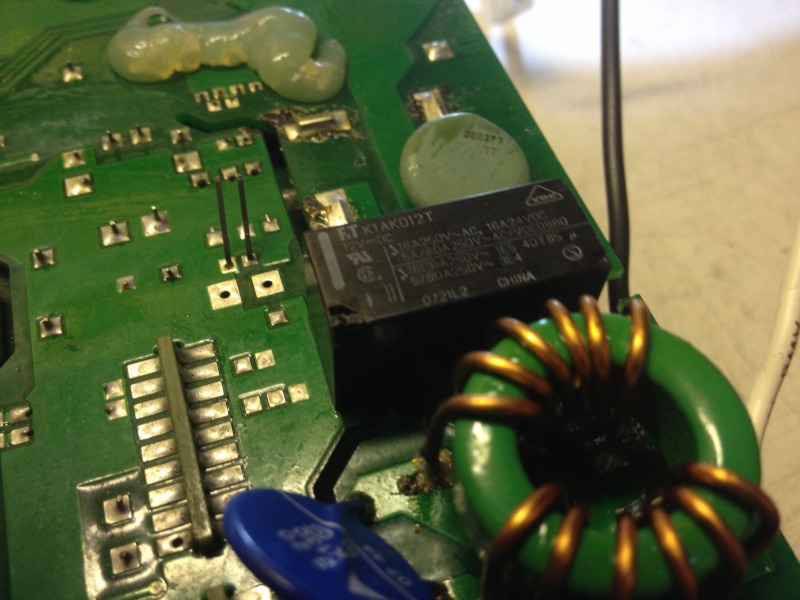

I have emailed the manufacturer for schematics, but they are unable to help me. From my understanding the machine uses dual IGBTs to output DC welding current. I have attached some photos and would like to say thanks in advance if anyone can offer assistance.

I have emailed the manufacturer for schematics, but they are unable to help me. From my understanding the machine uses dual IGBTs to output DC welding current. I have attached some photos and would like to say thanks in advance if anyone can offer assistance.