Hank Fletcher

New Member

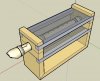

Here's a concept drawing of a recorder-playing robot I'm building. For now it's just the apparatus for holding the recorder. Solenoids will be attached to the acrylic sheet above and below the recorder to act as fingers. I'll post more pictures as I progress - I plan on having RCD-1 running by the end of August.