Hello

(First time poster with rusty familiarity with vaccuum tube audio amplifiers)

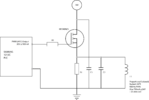

I am working with a Siemens 1212C PLC and looking to power a Burkert proportional solenoid via the PLC HSC outputs. Smaller solenoids have been successfully powered this way, but I need a bigger orifice size which requires a bigger solenoid. The maximum rated output of the PLC is 20V @ 500mA (ON) and the Burkert 2875 requires 24V @ 750mA to fully open. (In the smaller valves the 20V maximum is very nearly fully open and an acceptable compromise). Rather than add expensive AD/DA modules, is there a basic current gain MOSFET / transistor amp that I could employ? I'm not that familiar with transistor design, but have added a simple design that may work (?). I have a 24V supply to work with and don't need a big gain ~x2 current, and ideally a small voltage gain (which this design certainly won't provide). It's a 900Hz signal, so I imagine it can be a very simple circuit - added C2 to tune the output to a square wave and C1 to add some local capacitance. No doubt missing a diode.

Can anyone point me in the right direction? I have some IRF540N in the drawer, so if that works for easy prototyping - great!

Siemens 1212C

Burkert 2875

Thanks for any help,

Ben

(First time poster with rusty familiarity with vaccuum tube audio amplifiers)

I am working with a Siemens 1212C PLC and looking to power a Burkert proportional solenoid via the PLC HSC outputs. Smaller solenoids have been successfully powered this way, but I need a bigger orifice size which requires a bigger solenoid. The maximum rated output of the PLC is 20V @ 500mA (ON) and the Burkert 2875 requires 24V @ 750mA to fully open. (In the smaller valves the 20V maximum is very nearly fully open and an acceptable compromise). Rather than add expensive AD/DA modules, is there a basic current gain MOSFET / transistor amp that I could employ? I'm not that familiar with transistor design, but have added a simple design that may work (?). I have a 24V supply to work with and don't need a big gain ~x2 current, and ideally a small voltage gain (which this design certainly won't provide). It's a 900Hz signal, so I imagine it can be a very simple circuit - added C2 to tune the output to a square wave and C1 to add some local capacitance. No doubt missing a diode.

Can anyone point me in the right direction? I have some IRF540N in the drawer, so if that works for easy prototyping - great!

Siemens 1212C

Burkert 2875

Thanks for any help,

Ben