Fluence

New Member

Hi!

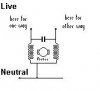

Since a image is worth more than words, here it is:

**broken link removed**

I've been thinking in the last hour in a solution to this problem, but i just can't come with something that will solve this...

It would be easy if the switches were like press-and-hold buttons, but they'r not. D:

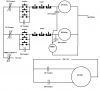

Since a image is worth more than words, here it is:

**broken link removed**

I've been thinking in the last hour in a solution to this problem, but i just can't come with something that will solve this...

It would be easy if the switches were like press-and-hold buttons, but they'r not. D:

Last edited: