Hi,

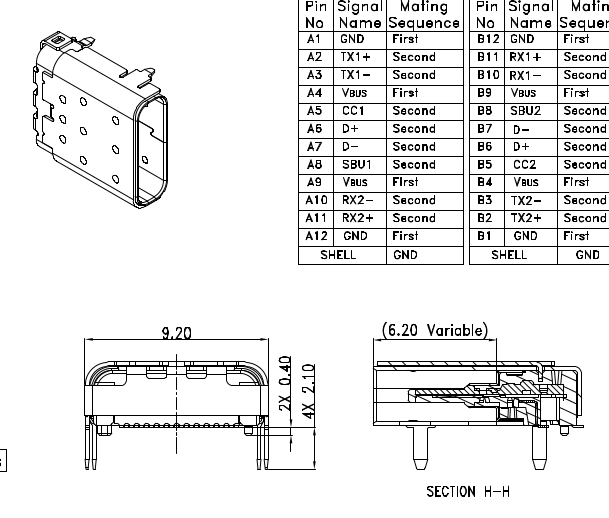

I have a small USB-C receptacle by Amphenol. It has 4 main legs which should be soldered (I think), however the length is of such that they don't come close to clearing a 0.8mm PCB thickness. On the attached pictures you can see I've hand soldered them and the solder has sunk. If they were solder pasted using PCBA and the same occurred is that an acceptable way to secure them?

Wondering what the process is!

Cheers, Andrew

I have a small USB-C receptacle by Amphenol. It has 4 main legs which should be soldered (I think), however the length is of such that they don't come close to clearing a 0.8mm PCB thickness. On the attached pictures you can see I've hand soldered them and the solder has sunk. If they were solder pasted using PCBA and the same occurred is that an acceptable way to secure them?

Wondering what the process is!

Cheers, Andrew