astronomerroyal

New Member

Hello,

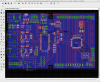

I'm not experienced with PCB layout and I've been spinning my wheels with this one for a while now (see attachements). Was wondering if you could give me your 'first impressions' on the PCB design. I realise this is a lot to ask, so was just hoping for gut-feelings and pointing out egregious errors.

This layout is straight out of the Eagle autorouter, as part of an iterative procedure: autoroute ... make changes ... repeat. Initially, I've been using the number of vias as a 'goodness of layout' metric (down to 37 vias so far, seems acceptable). I've not made any superficial changes, such as spacing traces evenly, or making angles 45degrees...

The gadget is an intervalometer for making time-lapse movies with dSLR cameras. I've linked to a movie at the end.

Microcontroller-centric: two uCs 'Master 18F4620' and 'Slave 18F2520'

All digital (no analogue mixed in)

Power management at top left. Max DC current =150mA. Typically 50mA.

Jacks for camera at left

various headers (ICSP, keypad, various uC pins) along bottom, and top.

When LCD is plugged in to header (at top right), the right side of board is obscured (so no indicator lights, switches can be placed there).

Passes DRC. 100% traces laid. 37 vias.

I've tried to arrange 'functional units' sensibly around the uCs. Been following some tutorials, e.g.

https://www.electro-tech-online.com/custompdfs/2010/02/PCBDesignTutorialRevA.pdf

Q: Is autoroute ... adjust ... autoroute a good way to explore an initial layout? Is number of vias a good quantitative measure of 'goodness of fit'? If so, is there any sort of rule-of-thumb regarding the vias-vs-pins ratio?

Q: Do you know of any pedagogical books that are full of example layouts: idea -> schematic ->layout. I've read a lot of 'common sense' and 'best practices', but am looking for more concrete examples (i.e. hand-holding).

Q: How much do you imagine someone would charge to take my schematic and produce a board layout?

[video=vimeo;7663437]http://vimeo.com/7663437[/video]

I'm not experienced with PCB layout and I've been spinning my wheels with this one for a while now (see attachements). Was wondering if you could give me your 'first impressions' on the PCB design. I realise this is a lot to ask, so was just hoping for gut-feelings and pointing out egregious errors.

This layout is straight out of the Eagle autorouter, as part of an iterative procedure: autoroute ... make changes ... repeat. Initially, I've been using the number of vias as a 'goodness of layout' metric (down to 37 vias so far, seems acceptable). I've not made any superficial changes, such as spacing traces evenly, or making angles 45degrees...

The gadget is an intervalometer for making time-lapse movies with dSLR cameras. I've linked to a movie at the end.

Microcontroller-centric: two uCs 'Master 18F4620' and 'Slave 18F2520'

All digital (no analogue mixed in)

Power management at top left. Max DC current =150mA. Typically 50mA.

Jacks for camera at left

various headers (ICSP, keypad, various uC pins) along bottom, and top.

When LCD is plugged in to header (at top right), the right side of board is obscured (so no indicator lights, switches can be placed there).

Passes DRC. 100% traces laid. 37 vias.

I've tried to arrange 'functional units' sensibly around the uCs. Been following some tutorials, e.g.

https://www.electro-tech-online.com/custompdfs/2010/02/PCBDesignTutorialRevA.pdf

Q: Is autoroute ... adjust ... autoroute a good way to explore an initial layout? Is number of vias a good quantitative measure of 'goodness of fit'? If so, is there any sort of rule-of-thumb regarding the vias-vs-pins ratio?

Q: Do you know of any pedagogical books that are full of example layouts: idea -> schematic ->layout. I've read a lot of 'common sense' and 'best practices', but am looking for more concrete examples (i.e. hand-holding).

Q: How much do you imagine someone would charge to take my schematic and produce a board layout?

[video=vimeo;7663437]http://vimeo.com/7663437[/video]

Attachments

Last edited: