I'm trying to design a circuit using a Power MOSFET to drive a resistive load.

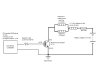

The way the circuit is hooked up now is the two grips are in series and connected directly to the ECU. I want to run the grips in parallel to increase the current, and power, to them. So basically I want to use the PWM signal from the ECU to drive a MOSFET so that the increased current goes through a $3 MOSFET instead of a $683 ECU. The attached diagram should help this all make sense.

Some questions I have:

1) Will this work?

2) Do I need the resistor to limit the current to the Gate? The ECU is capable of providing ~10A @ 12-14VDC.

3) What would the power to the grips and the series resistor be if the series resistor were 1.0 Ohm?

Any thoughts or suggestions (or totally re-design) would be greatly appreciated.

Thank,

Chad Wilson

The way the circuit is hooked up now is the two grips are in series and connected directly to the ECU. I want to run the grips in parallel to increase the current, and power, to them. So basically I want to use the PWM signal from the ECU to drive a MOSFET so that the increased current goes through a $3 MOSFET instead of a $683 ECU. The attached diagram should help this all make sense.

Some questions I have:

1) Will this work?

2) Do I need the resistor to limit the current to the Gate? The ECU is capable of providing ~10A @ 12-14VDC.

3) What would the power to the grips and the series resistor be if the series resistor were 1.0 Ohm?

Any thoughts or suggestions (or totally re-design) would be greatly appreciated.

Thank,

Chad Wilson