dreamtale

New Member

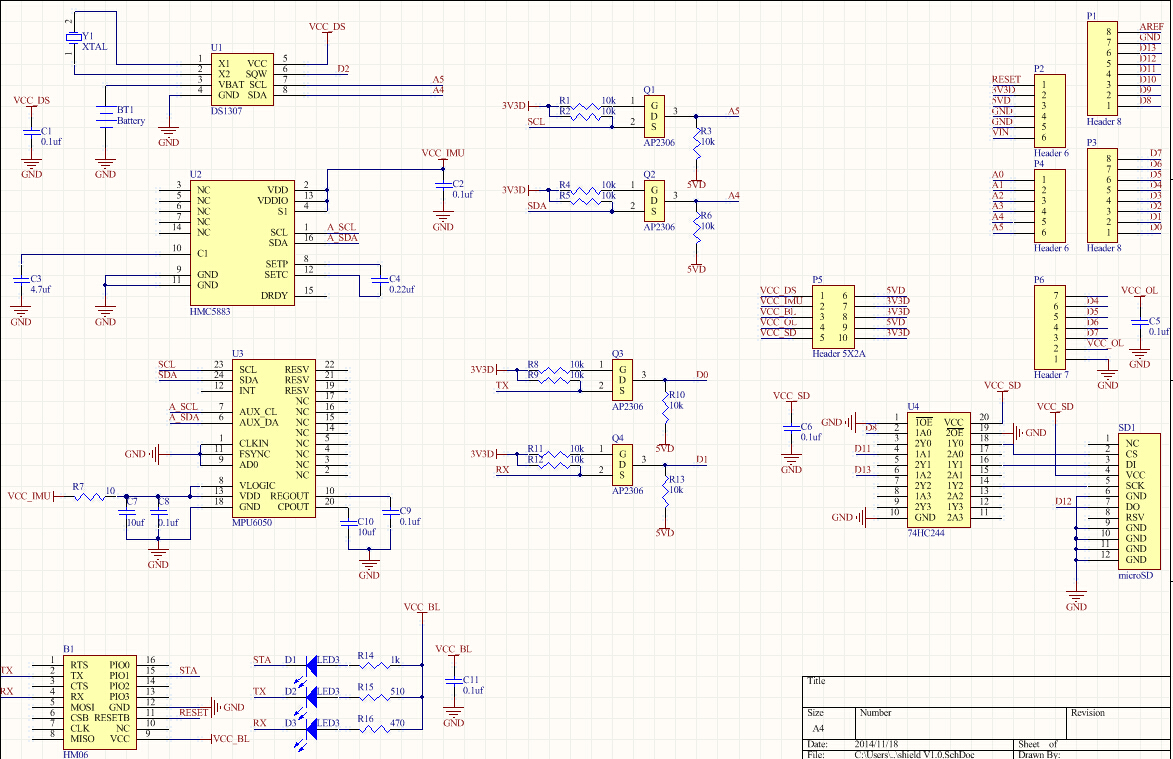

I had received a lot of advice.They point out my mistakes to help me improve.I am very grateful to them.After a modification over time, I sent my gerber files Smart-prototyping and production. I changed a lot, I was going to use PCF2129 replacement DS1307, but PCF2129 is expensive so I had to give up.I also modified schematic.

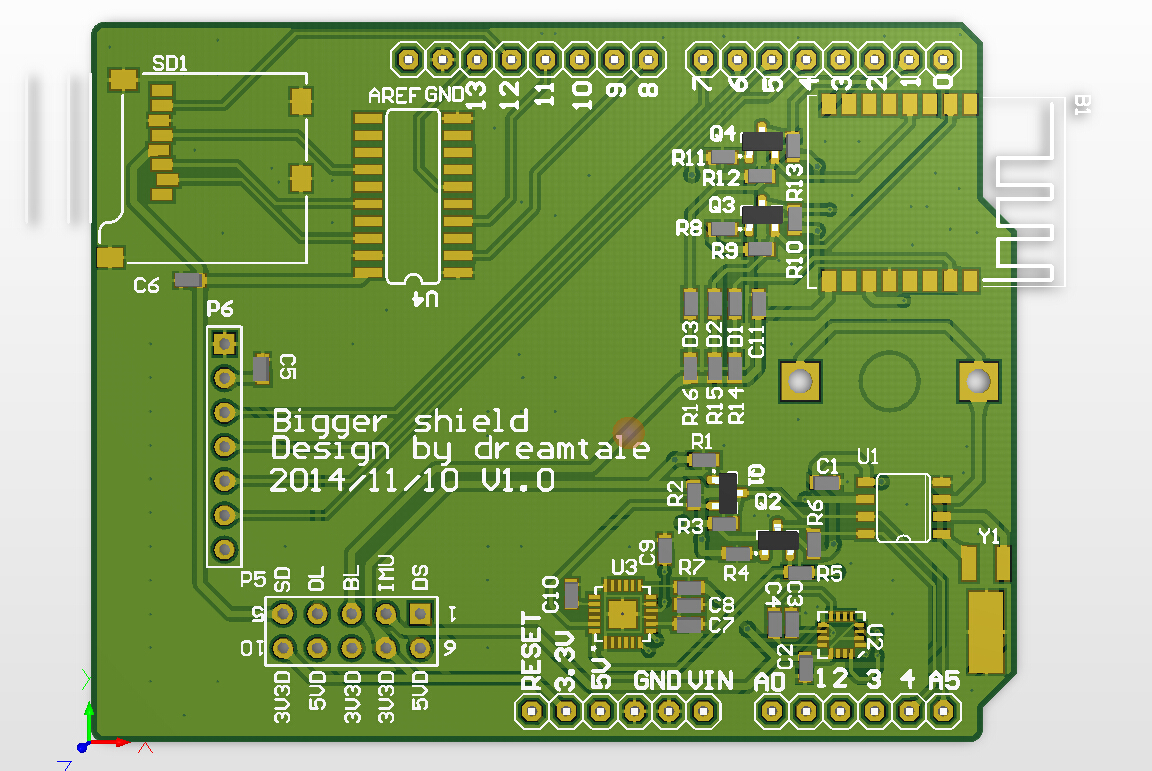

I had made a serious mistake, because avr328 output is 5V, but many modules work in 3.3V. If the direct connection, it may cause some unexpected problems. In the end, I had to drastically modify my schematic.I use the relevant characteristics of the NMOS.I made a simple level conversion circuit to make sure the system compatible with 5V and 3.3V.

In addition, according to the recommendation of some friends, I added MPU6050 as an acceleration sensor and an acceleration sensor. Now I have a complete PCB board 9-axis motion chip, it can know your stance and direction.

Many times, some projects need to use an SD card to store some parameters or some other data, I integrated the MicroSD card on the shield,I also set up a separate power jumper cap for each module, so that you can turn off some of the features when you does not require the use of certain modules.

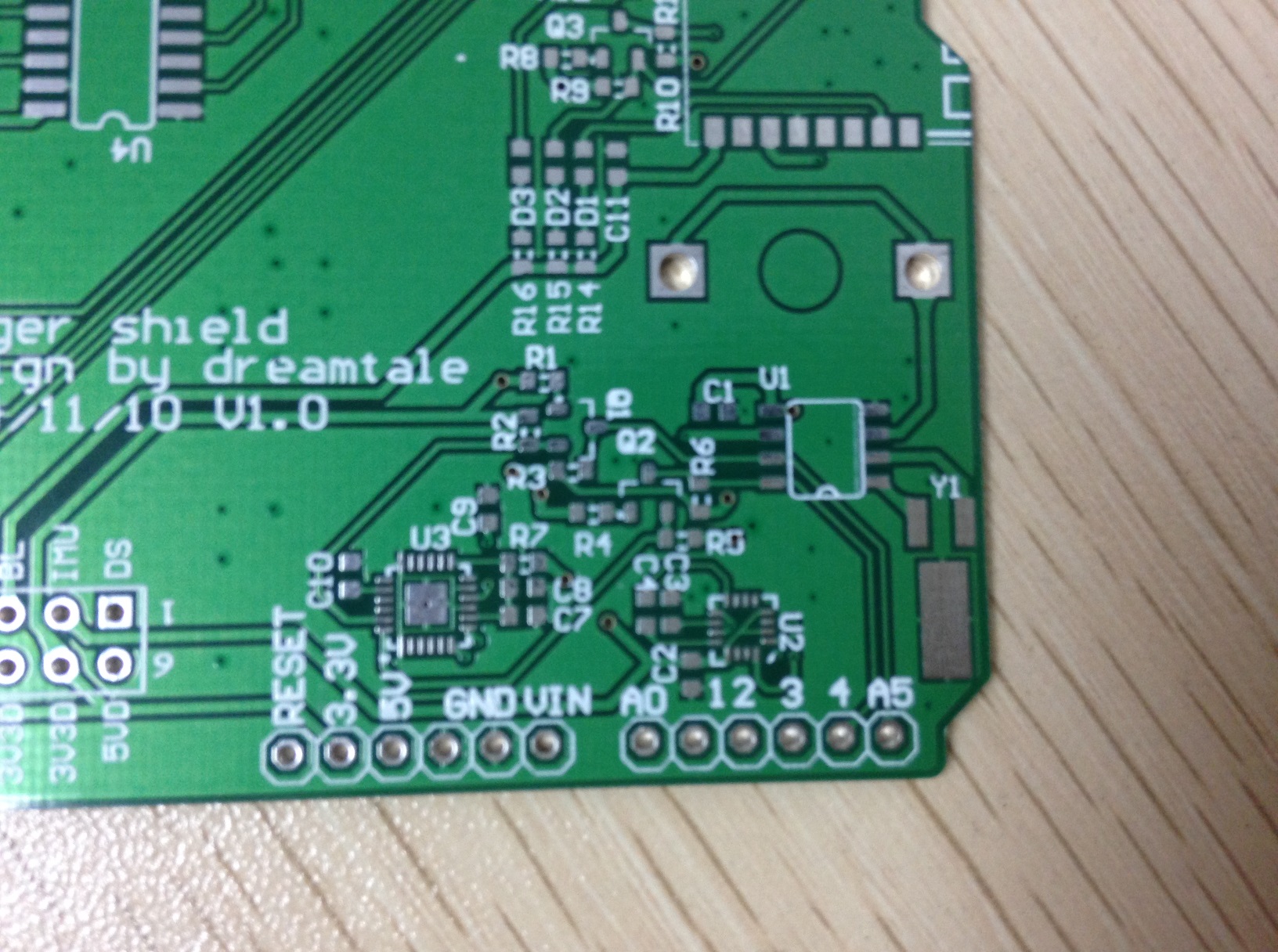

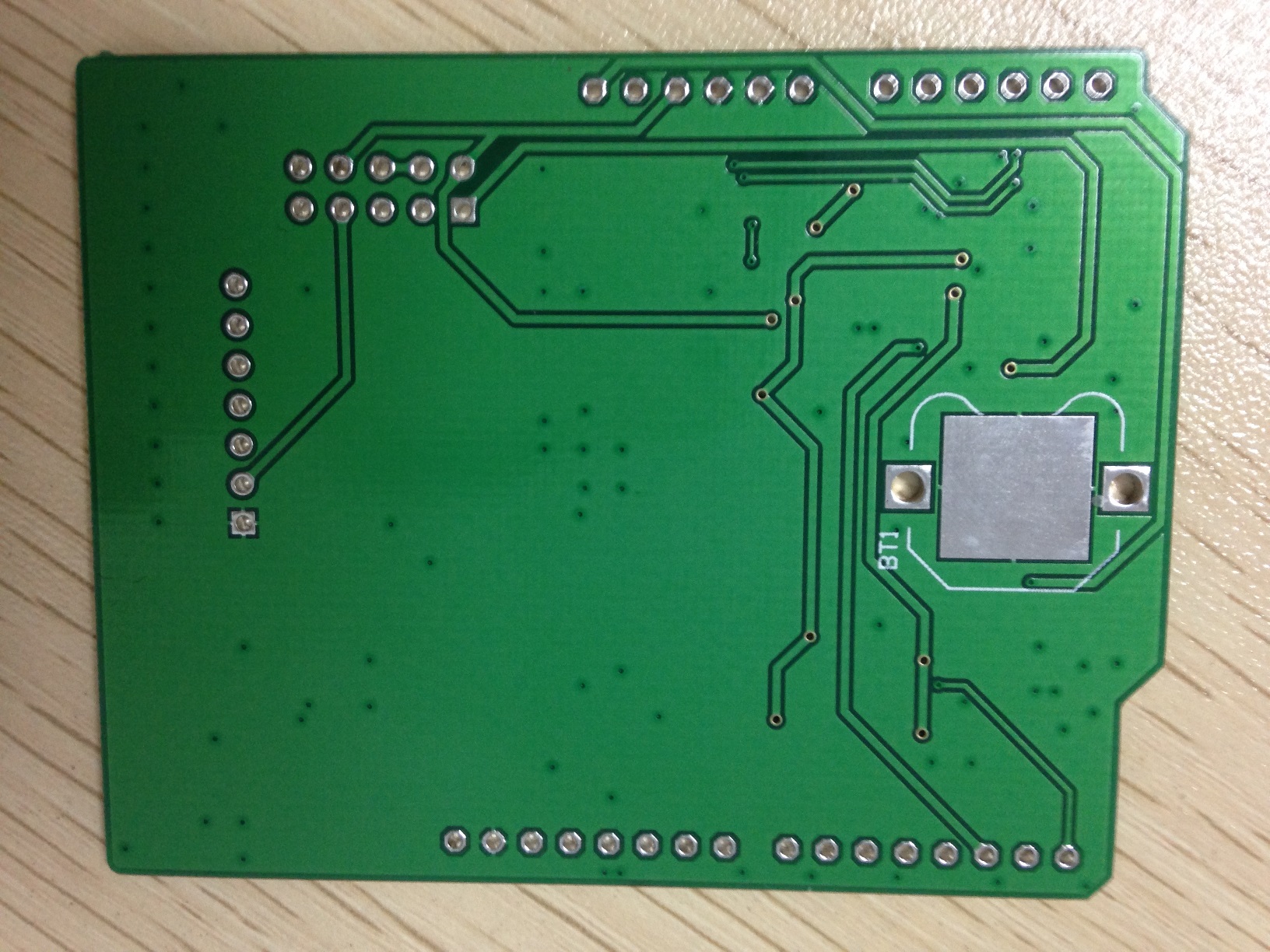

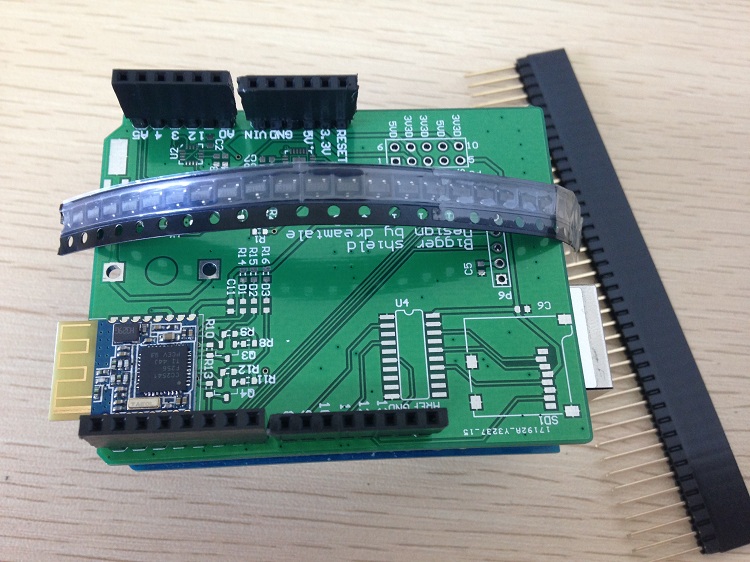

PCB board quality is very good, I designed a small PCB silk screen. It's clear.I recommend Smart-prototyping, Especially its online online quote system is very convenient, as long as you enter the dimensions and other requirements, the site can calculate the quote.

After I received my element, I will test each module. I will share my code.

--------------------------------------------------------------------------------------

2014/11/21 Updated

So far, I have only received part of Component, but some resistance and capacitance are still on the way.I really hope I can quickly get my element, I want go to sold them.

Unfortunately I used the wrong RTC footprint on PCB, I had to re-find some devices on the market, I'm afraid that I need to spend more time to complete it.

<Mod edit: Uploaded photos to ETO>

I had made a serious mistake, because avr328 output is 5V, but many modules work in 3.3V. If the direct connection, it may cause some unexpected problems. In the end, I had to drastically modify my schematic.I use the relevant characteristics of the NMOS.I made a simple level conversion circuit to make sure the system compatible with 5V and 3.3V.

In addition, according to the recommendation of some friends, I added MPU6050 as an acceleration sensor and an acceleration sensor. Now I have a complete PCB board 9-axis motion chip, it can know your stance and direction.

Many times, some projects need to use an SD card to store some parameters or some other data, I integrated the MicroSD card on the shield,I also set up a separate power jumper cap for each module, so that you can turn off some of the features when you does not require the use of certain modules.

PCB board quality is very good, I designed a small PCB silk screen. It's clear.I recommend Smart-prototyping, Especially its online online quote system is very convenient, as long as you enter the dimensions and other requirements, the site can calculate the quote.

After I received my element, I will test each module. I will share my code.

--------------------------------------------------------------------------------------

2014/11/21 Updated

So far, I have only received part of Component, but some resistance and capacitance are still on the way.I really hope I can quickly get my element, I want go to sold them.

Unfortunately I used the wrong RTC footprint on PCB, I had to re-find some devices on the market, I'm afraid that I need to spend more time to complete it.

<Mod edit: Uploaded photos to ETO>

Last edited: