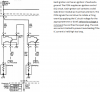

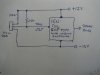

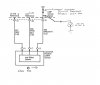

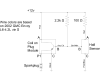

This is my first post. I have an old 1937 hit-n-mis stationary engine that is missing its complete ignition system. In an attempt to build my own system I salvaged a coil pack and hall sensor from a 2002 GMC Truck Envoy L6-4.2L. I plan to place the hall sensor near a pin on the cam shaft that used to operate the points. I know very little about electronics however and need some help. I'm including two pictures of what I found in AllData for these components. My question is can I connect the hall signal directly to the coil's switch transistor? I wont be using any part of the Envoy's PCM. I haven't tried it yet because I'm afraid I'll smoke the hall sensor and a replacement is more than $50. Another question, how do I deal with the engine stopped such that the hall sensor is closed? I don't want to discharge the battery or fry the coil as a result. Perhaps some kind of circuit could break the connection if it was left for more than 1/2 second.

Thank you for your assistance,

Thank you for your assistance,

Attachments

Last edited: