Hello,

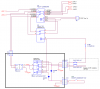

I'm trying to design a power switch for a project. The mains input is 240VAC and I've started with a few relays, e-off, power sw, and a temp switch in the loop. I want to use a mechanical single pole push button as the main power switch, but this way with the circuit I have if the e-off switch is engaged the main sw will remain closed, so no good. Then my second choice is to use a momentary sw, maybe capacitive or piezzo, but having a little issue designing around it. I will like to see what you think or other ways of doing this with minimal components as I have little space.

I'm trying to design a power switch for a project. The mains input is 240VAC and I've started with a few relays, e-off, power sw, and a temp switch in the loop. I want to use a mechanical single pole push button as the main power switch, but this way with the circuit I have if the e-off switch is engaged the main sw will remain closed, so no good. Then my second choice is to use a momentary sw, maybe capacitive or piezzo, but having a little issue designing around it. I will like to see what you think or other ways of doing this with minimal components as I have little space.

Attachments

Last edited: