GH Crash

Member

I need help in designing a simple LI protection circuit.

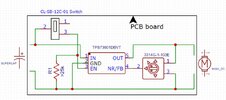

Circuit basis : LIC, lithium ion capacitors, have a minimum voltage limit. Discharging them and/or storing them with their remaining charge below that minimum voltage will damage or destroy the capacitor. The circuit to be designed would be placed between the capacitor and the load. It would interrupt the current flow when the capacitor voltage dropped to its minimum allowable voltage. The circuit will be used in environments where size and weight are a major concern. The LIC(power source) would have a capacitance between 10F and 100F with a maximum voltage rating around 5 volts. The minimum charge (voltage)limit of the LIC is around 2.1v. The load would be a small coreless DC motor typically rated below 10 watts at a maximum voltage of 4volts.

Here are the circuit requirements

Addition information: Supercapacitor (EDLC) have been used for years as an energy source for electric free flight model aircraft that use small coreless DC motors connected to the propeller. The normal flight consists of charging the capacitor, switching on the motor, and launching the plane. The motor powers the plane until the capacitor is completely discharged. LIC, lithium-ion capacitors (sometimes called hybrid capacitors) are starting to replace the supercapacitor due to their lighter weigh and greater power density. Unfortunately completely discharging a LIC to a zero volt potential sooner or later will destroy the capacitor. The LIC protection circuit would prevent the motor from completely discharging the capacitor.

Questions:

What type of circuit would suggest as the best approach to meeting the goals and requirements given? How would go about protecting the LIC?

I posted this help request in another electronics forum. One of the answers given was to use the same circuit used to protect Lipo batteries. That was tried and the results were mixed, seemed to work for one individual, completely failed for another individual.

Circuit basis : LIC, lithium ion capacitors, have a minimum voltage limit. Discharging them and/or storing them with their remaining charge below that minimum voltage will damage or destroy the capacitor. The circuit to be designed would be placed between the capacitor and the load. It would interrupt the current flow when the capacitor voltage dropped to its minimum allowable voltage. The circuit will be used in environments where size and weight are a major concern. The LIC(power source) would have a capacitance between 10F and 100F with a maximum voltage rating around 5 volts. The minimum charge (voltage)limit of the LIC is around 2.1v. The load would be a small coreless DC motor typically rated below 10 watts at a maximum voltage of 4volts.

Here are the circuit requirements

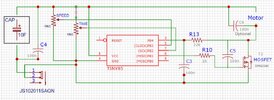

- The circuit shall not appreciable change the operating characteristics of the load. That is, that the motor's input voltage and amperage and operating speed should be virtually the same, within +/- 2%, with or without the protection circuit in the system.

- The circuit must be capable of handling currents up to 5 amps.

- The circuit should operate satisfactorily at LIC voltages between one point five and six volts DC.

- Quiescent current flow should be minimized as much as possible. Quiescent current flow of for the entire circuit should be less than 10uA.

- The completed circuit, with all components should fit on as small a PCB as possible, preferably under 15mm by 15mm square.

- The completed circuit must be light, under 0.75 grams max weight, under 0.5g ideally.

- Items, or conditions, not specifically mentioned in the requirements are left up to the designer's discretion. Items such as component availability, cost, specification tolerances have no significant bearing upon the circuit design.

Addition information: Supercapacitor (EDLC) have been used for years as an energy source for electric free flight model aircraft that use small coreless DC motors connected to the propeller. The normal flight consists of charging the capacitor, switching on the motor, and launching the plane. The motor powers the plane until the capacitor is completely discharged. LIC, lithium-ion capacitors (sometimes called hybrid capacitors) are starting to replace the supercapacitor due to their lighter weigh and greater power density. Unfortunately completely discharging a LIC to a zero volt potential sooner or later will destroy the capacitor. The LIC protection circuit would prevent the motor from completely discharging the capacitor.

Questions:

What type of circuit would suggest as the best approach to meeting the goals and requirements given? How would go about protecting the LIC?

I posted this help request in another electronics forum. One of the answers given was to use the same circuit used to protect Lipo batteries. That was tried and the results were mixed, seemed to work for one individual, completely failed for another individual.