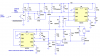

Sorry for yet another one of these threads but... I want to build a laser trip wire. Every thing ive seen has info. missing, or I need to program a pic.

This is what I want to have happen: when the laser(from a pen) is broken I want to spin a 9v motor untill the beam is re connected.

If the beam is broken for just a fraction of a second I would like the motor to spin for about .5 second.

I would also like it if I could controll how fast the motor spins.

I'm trying to keep this cheap and simple. I can read schematics but other than that im basically dumb at this.

I'll paypal some $ to the person that posts a good schematic. o

oh and please dont bash others ideas inless it's really necesary.

This is what I want to have happen: when the laser(from a pen) is broken I want to spin a 9v motor untill the beam is re connected.

If the beam is broken for just a fraction of a second I would like the motor to spin for about .5 second.

I would also like it if I could controll how fast the motor spins.

I'm trying to keep this cheap and simple. I can read schematics but other than that im basically dumb at this.

I'll paypal some $ to the person that posts a good schematic. o

oh and please dont bash others ideas inless it's really necesary.