I have a problem with PWM controller.

original thread about it here: https://www.electro-tech-online.com/threads/need-help-with-pwm-mosfet.88471/

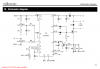

I use velleman K8004 PWM controller card to drive DC motor.

DC TO PULSE WIDTH MODULATOR

Manual:

https://www.electro-tech-online.com/custompdfs/2010/08/illustrated_assembly_manual_k8004_rev3.pdf

I have Canon Printer Carriage Motor QK1-1500

TN425813 12V DC.

**broken link removed**

**broken link removed**

**broken link removed**

I control the motor via 1K pot. I use internal reference voltage to control the motor speed. But as the load changes so does the motor speed.

How can I adjust the speed like I do now via POT but be able to lock it?

Please see manual page 8 for connection options.

I have the timing disc and 4 contact sensor (hall sensor?) from Canon printer that I could use. Or is there another easier way?

Thank you.

original thread about it here: https://www.electro-tech-online.com/threads/need-help-with-pwm-mosfet.88471/

I use velleman K8004 PWM controller card to drive DC motor.

DC TO PULSE WIDTH MODULATOR

Manual:

https://www.electro-tech-online.com/custompdfs/2010/08/illustrated_assembly_manual_k8004_rev3.pdf

I have Canon Printer Carriage Motor QK1-1500

TN425813 12V DC.

**broken link removed**

**broken link removed**

**broken link removed**

I control the motor via 1K pot. I use internal reference voltage to control the motor speed. But as the load changes so does the motor speed.

How can I adjust the speed like I do now via POT but be able to lock it?

Please see manual page 8 for connection options.

I have the timing disc and 4 contact sensor (hall sensor?) from Canon printer that I could use. Or is there another easier way?

Thank you.

Last edited: