Via EDN, Adem Kaya's article, Check Battery Capacity With a Simple Test Method, looks like it should detect low batteries well before failure is imminent. It's simple enough to implement on any micro with an ADC.

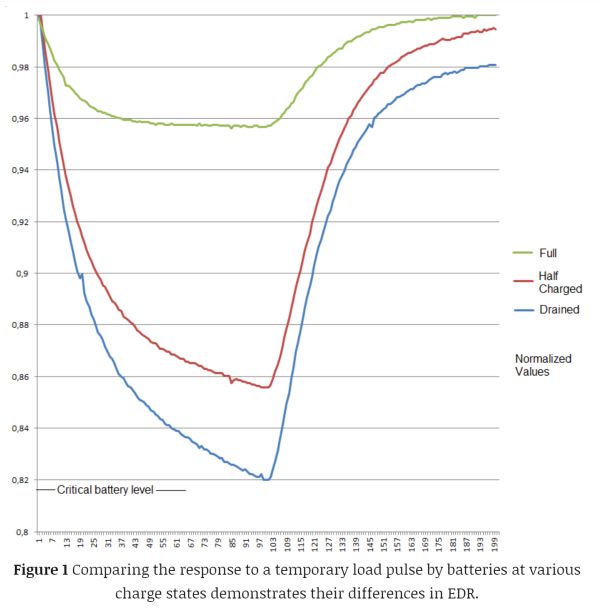

Measuring open-circuit battery voltage is nearly meaningless. This method with an impressive name – electrochemical dynamic response (EDR) – uses a resistor to momentarily apply maximum load while measuring the dip in battery voltage and the recovery time to full voltage to provide a more reliable battery test. With some experience, you should be able to estimate remaining battery life. The curves below show this characteristic.

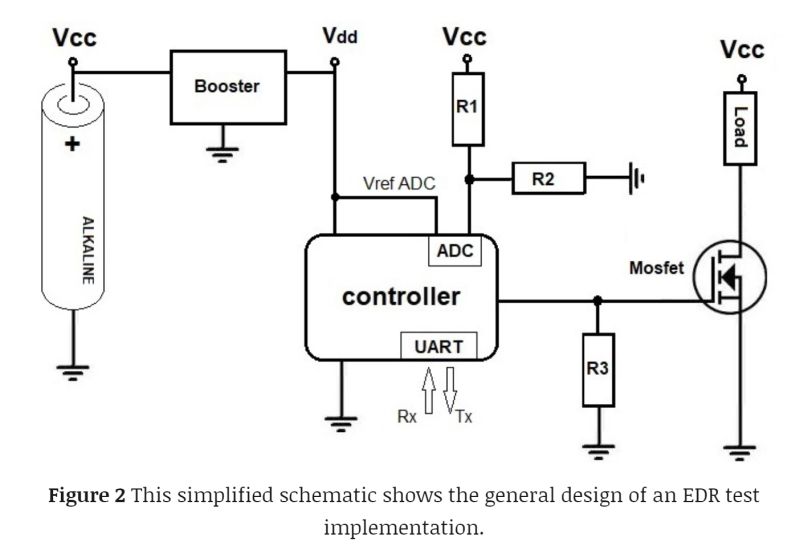

The schematic is pretty simple, primarily adding a load resistor and mosfet. The "booster" is to provide a stable reference for the ADC. Using something like a PIC18F-series (and a multitude of others) having a built in reference and the ability of measuring Vcc without any external connections, the booster and voltage voltage divider can be eliminated, making this circuit is almost trivial to add to a battery-operated project.

While I don't think "electrochemical dynamic response" is an earth-shaking idea (more like common knowledge), using it to more-accurately estimate battery life is a great idea. Check out the full article linked above.

Measuring open-circuit battery voltage is nearly meaningless. This method with an impressive name – electrochemical dynamic response (EDR) – uses a resistor to momentarily apply maximum load while measuring the dip in battery voltage and the recovery time to full voltage to provide a more reliable battery test. With some experience, you should be able to estimate remaining battery life. The curves below show this characteristic.

The schematic is pretty simple, primarily adding a load resistor and mosfet. The "booster" is to provide a stable reference for the ADC. Using something like a PIC18F-series (and a multitude of others) having a built in reference and the ability of measuring Vcc without any external connections, the booster and voltage voltage divider can be eliminated, making this circuit is almost trivial to add to a battery-operated project.

While I don't think "electrochemical dynamic response" is an earth-shaking idea (more like common knowledge), using it to more-accurately estimate battery life is a great idea. Check out the full article linked above.