crashedrobot

New Member

Hello Everyone,

I want to start off by saying that I am very new to working with electronics/circuits, so please be patient with me.

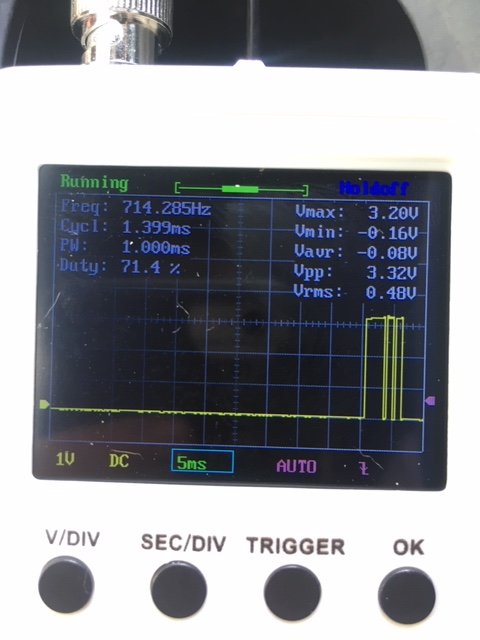

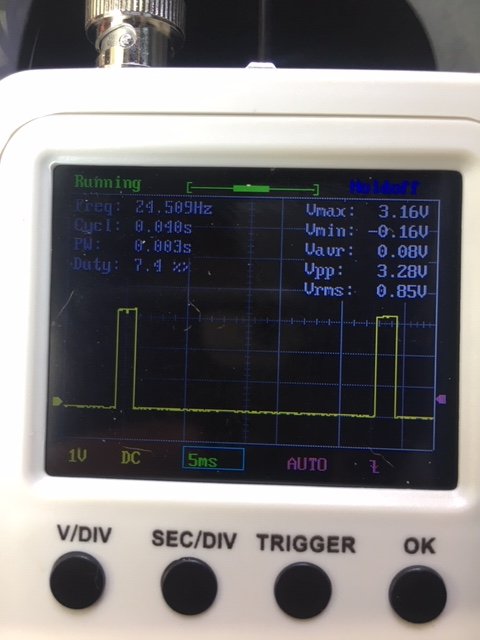

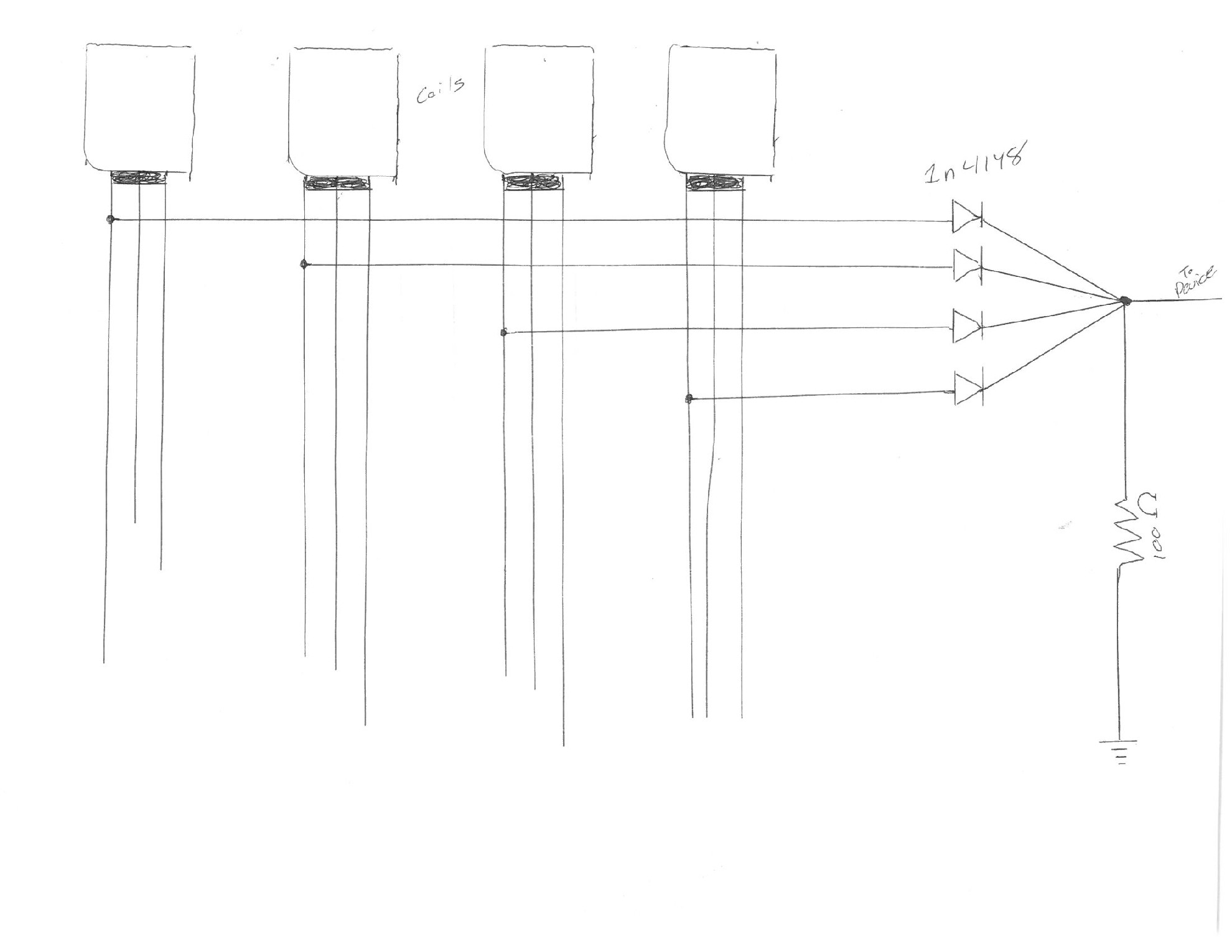

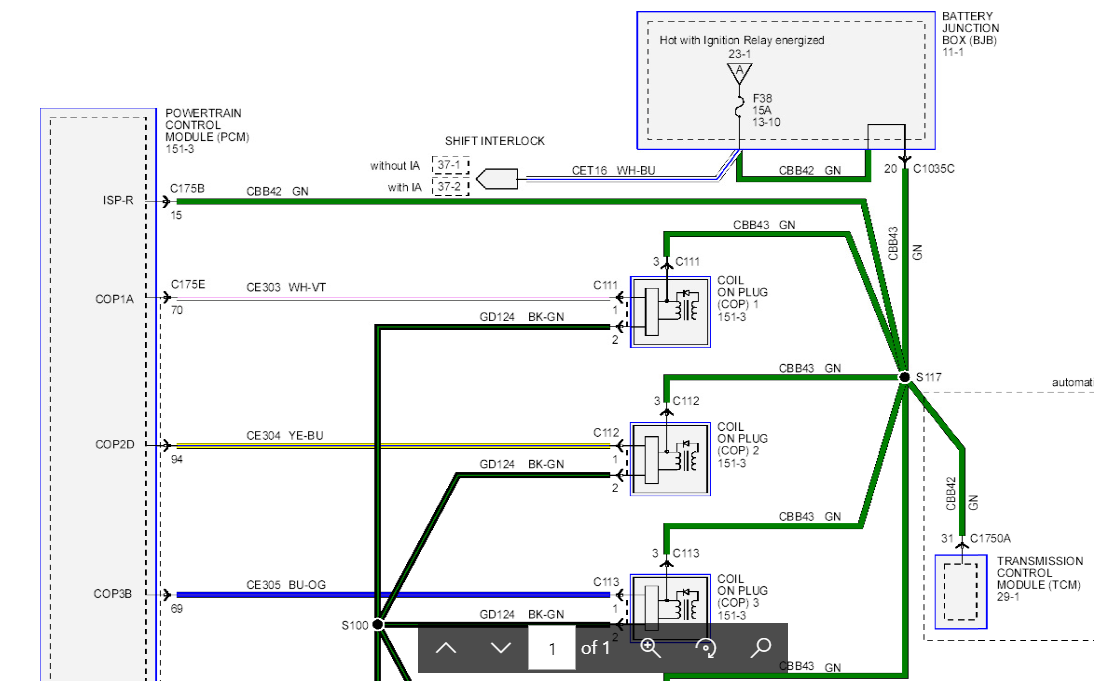

So I am wanting to get a signal from my ignition coils for an arduino/raspberry pi tachometer project. The issue I'm having is that at low rpms (~1200 and below), the signal gets a bit noisy as shown by the two extra spikes following the main spike. Once I get on the throttle, those extra spikes go away and my arduino reads the frequency very well. Is there anything I can do to clean up that signal? I attached the schematic I used (although I only tapped into one coil wire) and the coil on plug wiring diagram. Let me know if any other information is needed.

Thanks!

I want to start off by saying that I am very new to working with electronics/circuits, so please be patient with me.

So I am wanting to get a signal from my ignition coils for an arduino/raspberry pi tachometer project. The issue I'm having is that at low rpms (~1200 and below), the signal gets a bit noisy as shown by the two extra spikes following the main spike. Once I get on the throttle, those extra spikes go away and my arduino reads the frequency very well. Is there anything I can do to clean up that signal? I attached the schematic I used (although I only tapped into one coil wire) and the coil on plug wiring diagram. Let me know if any other information is needed.

Thanks!