Hi friends,

I've just got the ADXL180 accelerometer from Analog Devices. I was so excited after seeing the specifications that I just ordered it without realizing how I would solder it in the first place!!

Now, could somebody please indicate how to solder this tiny LFCSP package with pads hidden beneath??

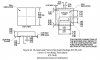

Here is an image from datasheet showing the package outline and dimensions.

I've just got the ADXL180 accelerometer from Analog Devices. I was so excited after seeing the specifications that I just ordered it without realizing how I would solder it in the first place!!

Now, could somebody please indicate how to solder this tiny LFCSP package with pads hidden beneath??

Here is an image from datasheet showing the package outline and dimensions.