SentinelAeon

Member

Hello,

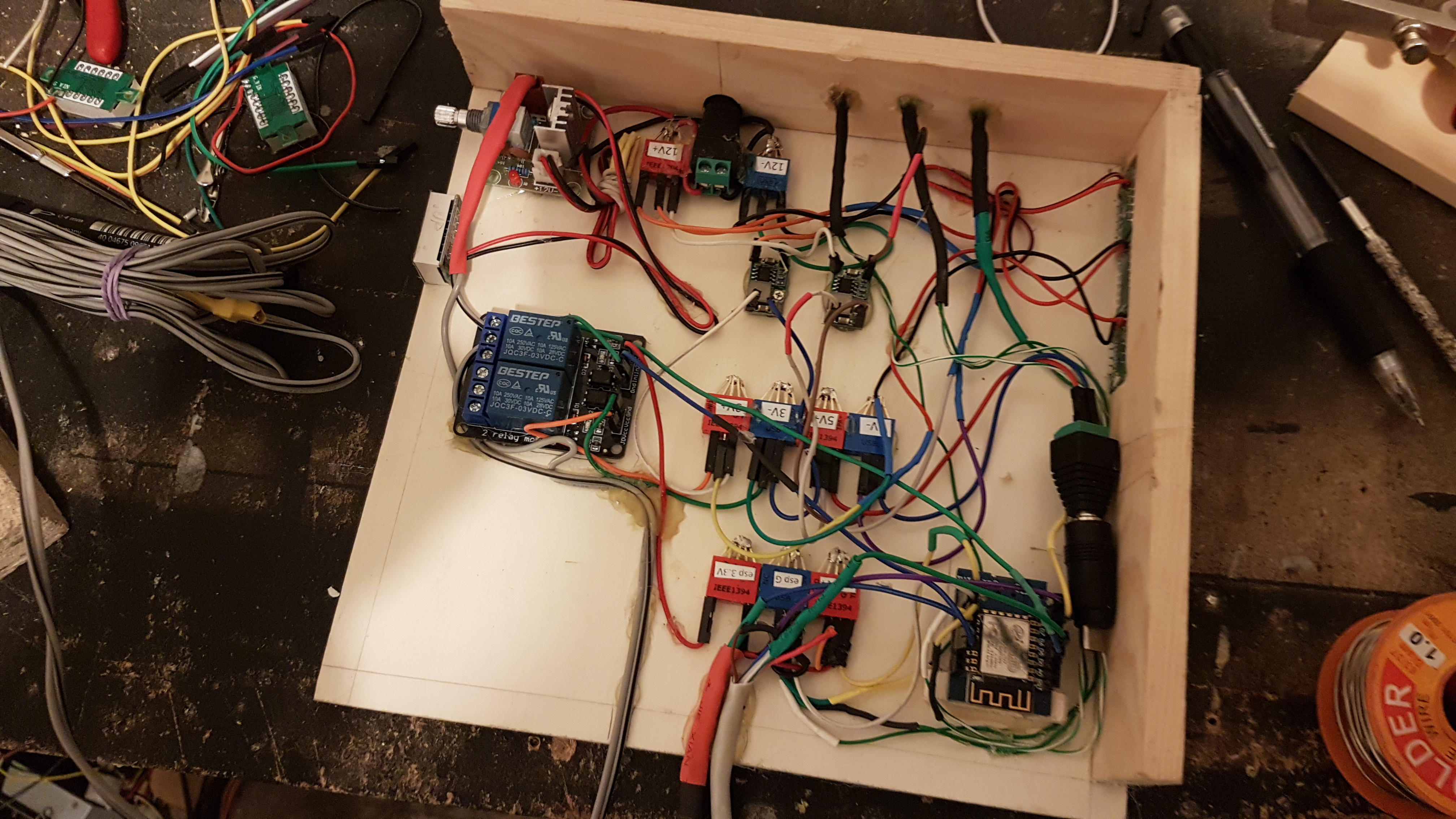

I regularly make some small projects, mostly for me, sometimes for my friends. They include some simple components, like ESP8266, some step-downs/step-ups, some relays, some voltage led displays, etc. Nothing fancy.

I attached an example of 1 of my projects. Now the problem i am having is, it is really hard to replace a single element if it goes bad. Imagine replacing the little step-down, i would need my equipment if i was to replace it at my friends place.

I am looking for a better way to design and make my little projects. It would be great if all my components, including ESP8266 could be simply swapped with a working part, using the little leg elements (in a similar way that you can replace a fan in a computer, simply unplug it, plug a different one in). Also all those wires are dead weight, it would be a lot easier if i had like a circuit board with all those connection and i would only solver the elements to the appropriate location. But i am wondering how much would a custom circuit board cost - would it make sense, since all other components you see are very cheap (probably everything on the image combined is around 10$ .. )

I am just starting with electronic projects and would be really glad for some advices.

I regularly make some small projects, mostly for me, sometimes for my friends. They include some simple components, like ESP8266, some step-downs/step-ups, some relays, some voltage led displays, etc. Nothing fancy.

I attached an example of 1 of my projects. Now the problem i am having is, it is really hard to replace a single element if it goes bad. Imagine replacing the little step-down, i would need my equipment if i was to replace it at my friends place.

I am looking for a better way to design and make my little projects. It would be great if all my components, including ESP8266 could be simply swapped with a working part, using the little leg elements (in a similar way that you can replace a fan in a computer, simply unplug it, plug a different one in). Also all those wires are dead weight, it would be a lot easier if i had like a circuit board with all those connection and i would only solver the elements to the appropriate location. But i am wondering how much would a custom circuit board cost - would it make sense, since all other components you see are very cheap (probably everything on the image combined is around 10$ .. )

I am just starting with electronic projects and would be really glad for some advices.