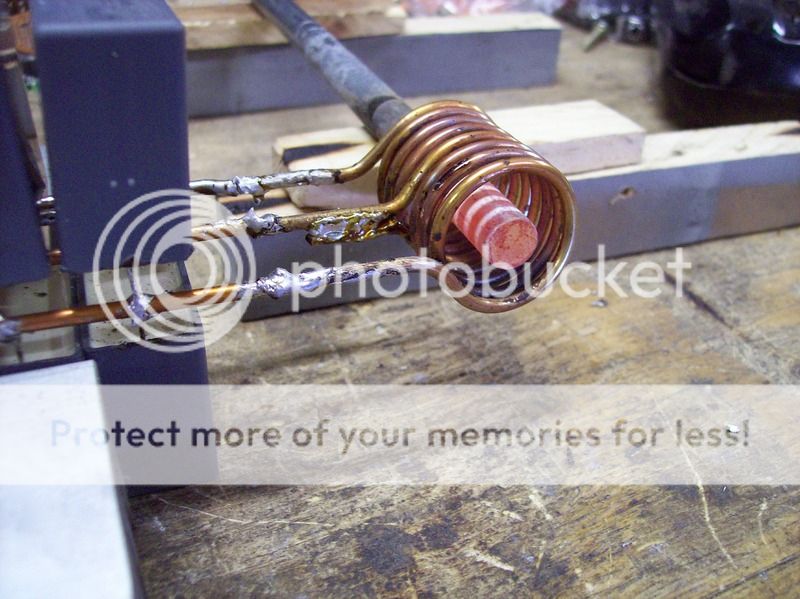

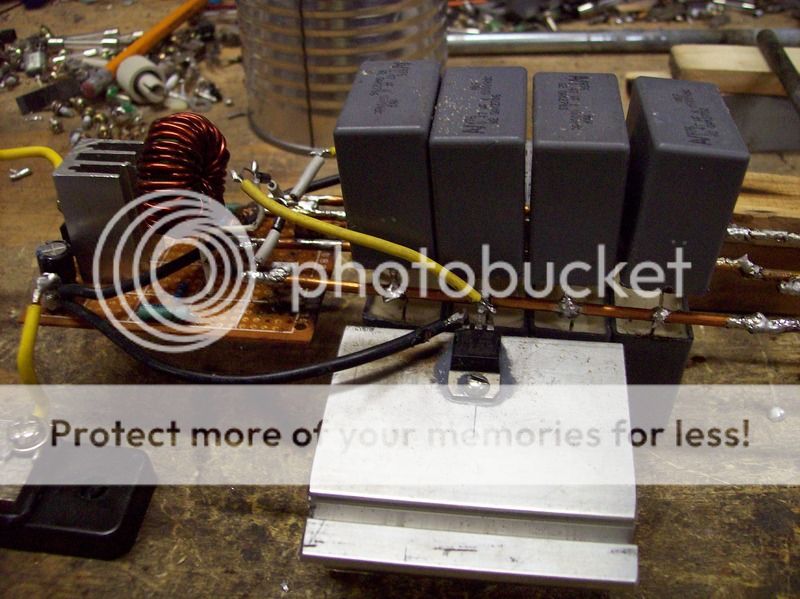

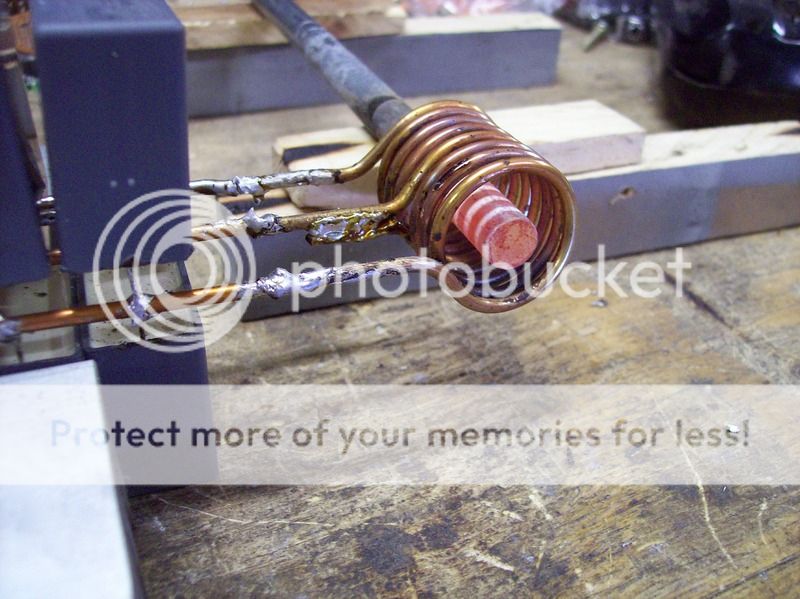

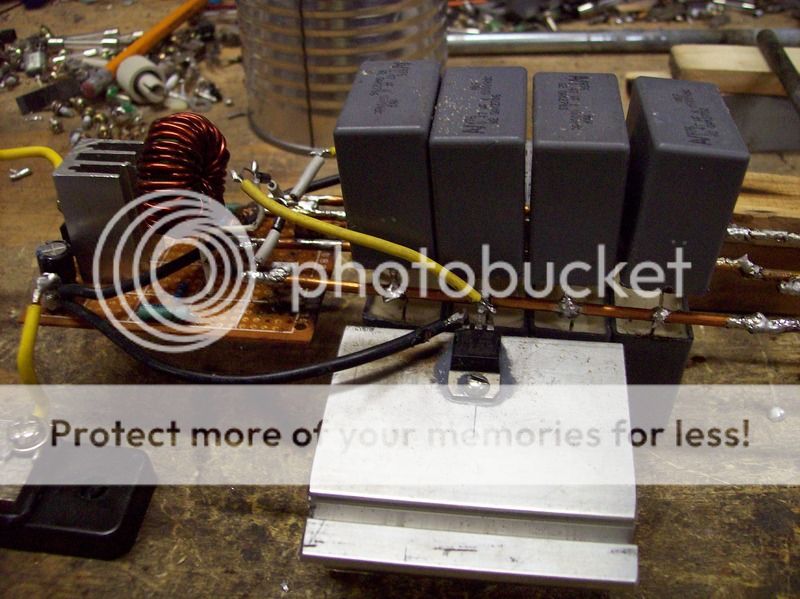

My amp meter arrived now I know for sure how many amps the circuit is. 36 amps with the 3/8" diameter metal rod and 27 amps with the 1/4" metal rod.

21.1 vdc power supply with no load.

17.53 vdc at 6 amps no load in coil. 105 watts

13.7 vdc at 27 amps with 1/4" load. 369.9 watts

13.1 vdc at 36 amps with 3/8" load. 471.6 watts

I dont understand why I can not get a hotter part? I need the part to be about 200 degrees hotter. The temperature I have is slightly too low for metal forming.

21.1 vdc power supply with no load.

17.53 vdc at 6 amps no load in coil. 105 watts

13.7 vdc at 27 amps with 1/4" load. 369.9 watts

13.1 vdc at 36 amps with 3/8" load. 471.6 watts

I dont understand why I can not get a hotter part? I need the part to be about 200 degrees hotter. The temperature I have is slightly too low for metal forming.

Last edited:

. I have stopped assisting him.

. I have stopped assisting him.