Hi,

Just joined the site, my Name is Nick and I'm from London but now

in Switzerland. For a hobby and to make a bit of cash, I restore 2 stroke

motorcycles from the 1980's...

At the moment I am trying to make a small improvement to a bike by

fitting a gear position indicator using an LED 8 segment display. I have

made this and using a matrix of diodes have 7 different earths that light

up my display as I want, and these earths correspond to the gearbox

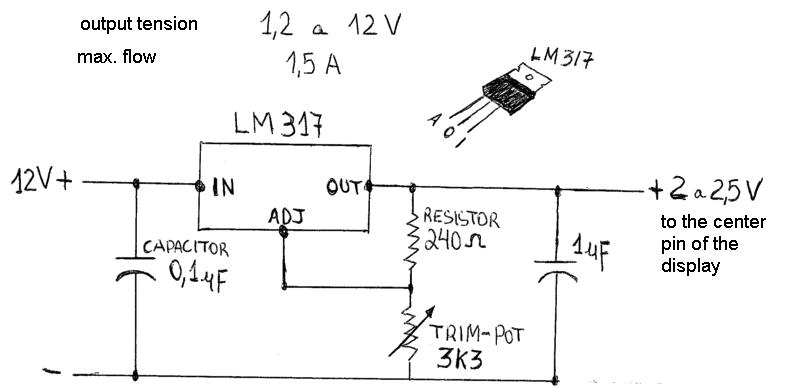

positions and all is well. What I now have to do is make a transformer to

convert the 12V DC from the battery of the bike to 2.5V DC for my display...

This circuit has been suggested to me and I have all the components

to make it, but before I connect it up to my brand new wiring loom which

cost £250, could any of you see any problems with it, or if it will even work at all

as I don't want to ruin anything on my new loom or battery. I am a mechanical

engineer with 25 years experience, so the bike and its mechanics are no problem,

but my electrical knowledge is very limited. Any help would be greatly appreciated.

Many thanks, Nick.

Just joined the site, my Name is Nick and I'm from London but now

in Switzerland. For a hobby and to make a bit of cash, I restore 2 stroke

motorcycles from the 1980's...

At the moment I am trying to make a small improvement to a bike by

fitting a gear position indicator using an LED 8 segment display. I have

made this and using a matrix of diodes have 7 different earths that light

up my display as I want, and these earths correspond to the gearbox

positions and all is well. What I now have to do is make a transformer to

convert the 12V DC from the battery of the bike to 2.5V DC for my display...

This circuit has been suggested to me and I have all the components

to make it, but before I connect it up to my brand new wiring loom which

cost £250, could any of you see any problems with it, or if it will even work at all

as I don't want to ruin anything on my new loom or battery. I am a mechanical

engineer with 25 years experience, so the bike and its mechanics are no problem,

but my electrical knowledge is very limited. Any help would be greatly appreciated.

Many thanks, Nick.