Hello all,

I have a project that requires a gear motor to be reduced to 1 rpm. Currently the motor is rated for 1700rpm, and already geared 30:1 for 56.7rpm. The plan for further reduction is to mate the shaft into another speed reducer of 50:1. I am interested to know what will be the best capacitor and arrangement to have this plug directly into the wall with a speed controller to perhaps get the range of rpm between 1.25rpm and .75rpm. We need the motor to be reliable for a lot of on/off. Motor also comes with two blue and two black wires.

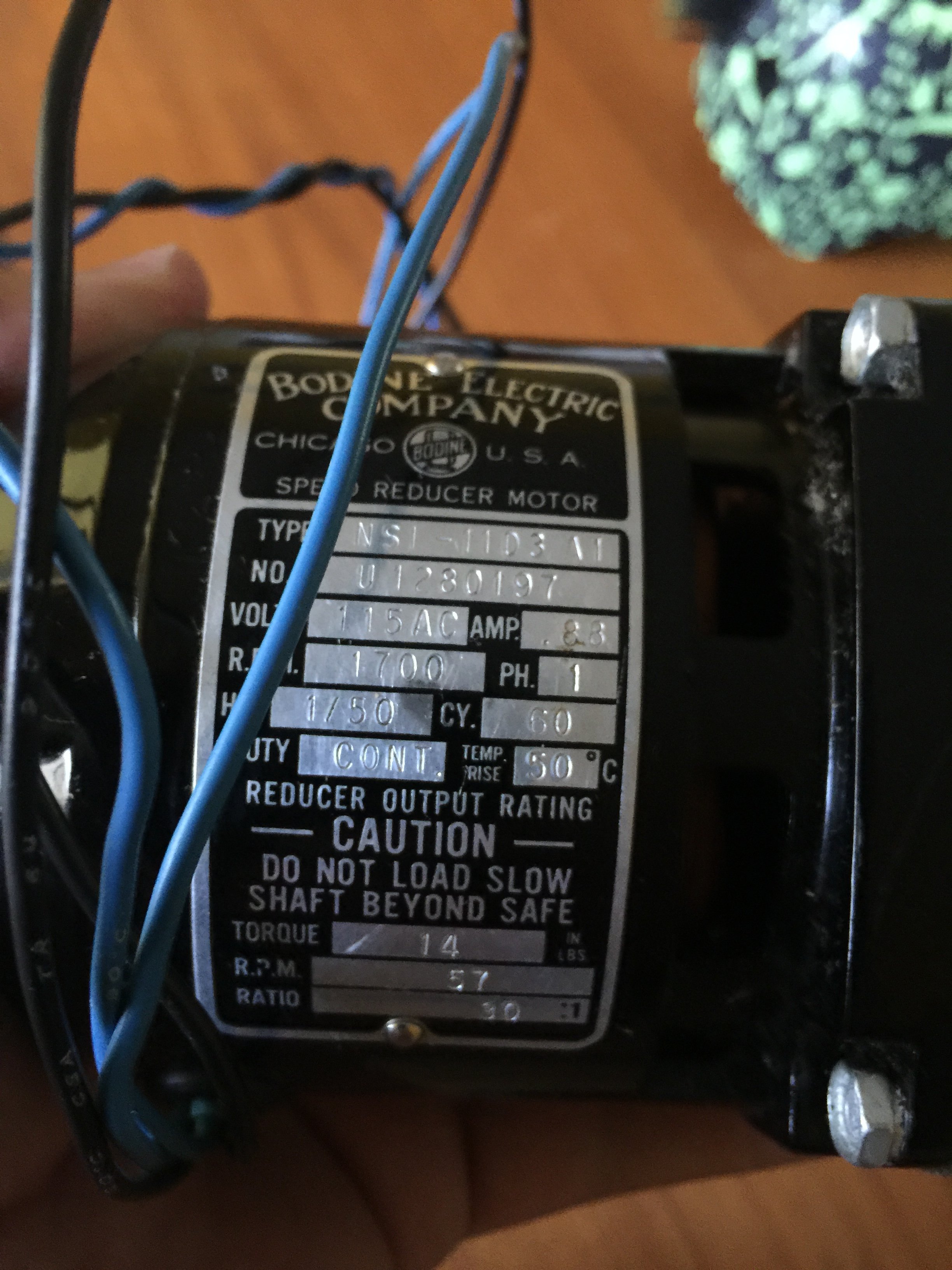

motor specs - bodine 115 ac, .88amp, 1700rpm, phase 1, 1/50hp, cy. 60

I have a project that requires a gear motor to be reduced to 1 rpm. Currently the motor is rated for 1700rpm, and already geared 30:1 for 56.7rpm. The plan for further reduction is to mate the shaft into another speed reducer of 50:1. I am interested to know what will be the best capacitor and arrangement to have this plug directly into the wall with a speed controller to perhaps get the range of rpm between 1.25rpm and .75rpm. We need the motor to be reliable for a lot of on/off. Motor also comes with two blue and two black wires.

motor specs - bodine 115 ac, .88amp, 1700rpm, phase 1, 1/50hp, cy. 60