Iawia

Member

Hi,

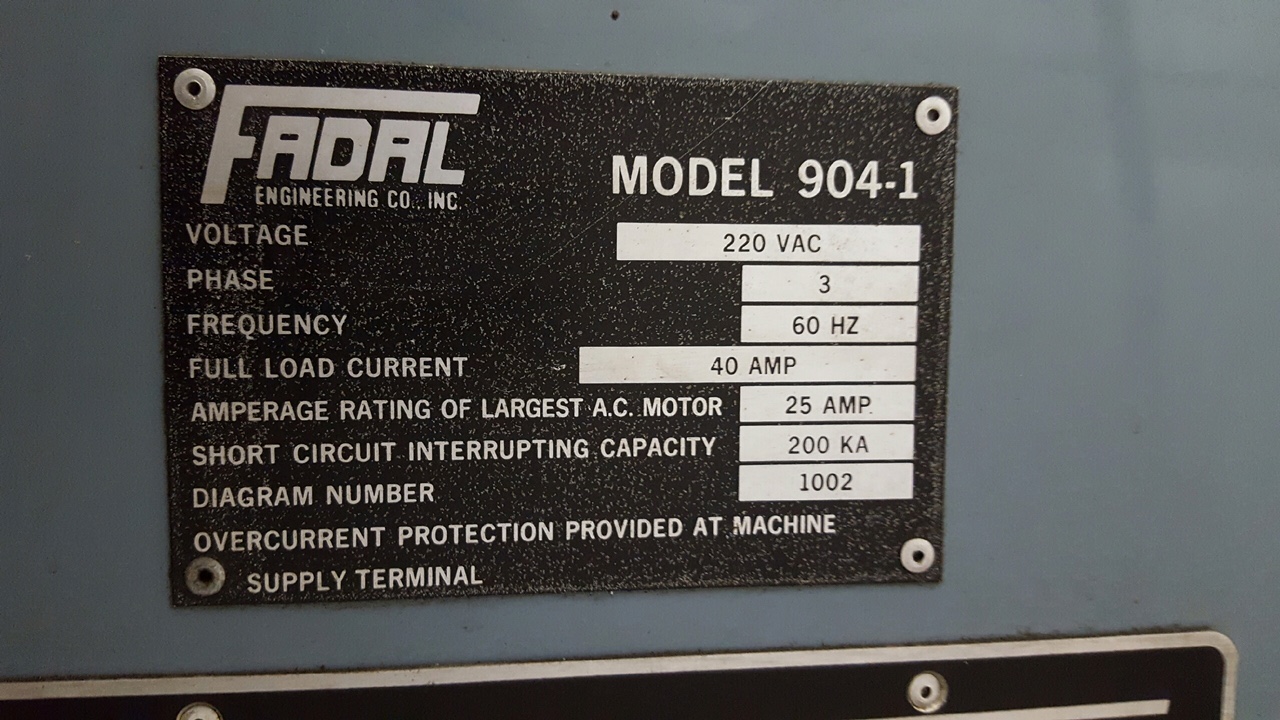

A friend of mine just purchased a Fadal CNC machine and put it in his garage. Thinking that the electrical hookup would not be a big deal from three phase 208v to household single phase 220v, it was too good of a machine to pass on so it was purchased.

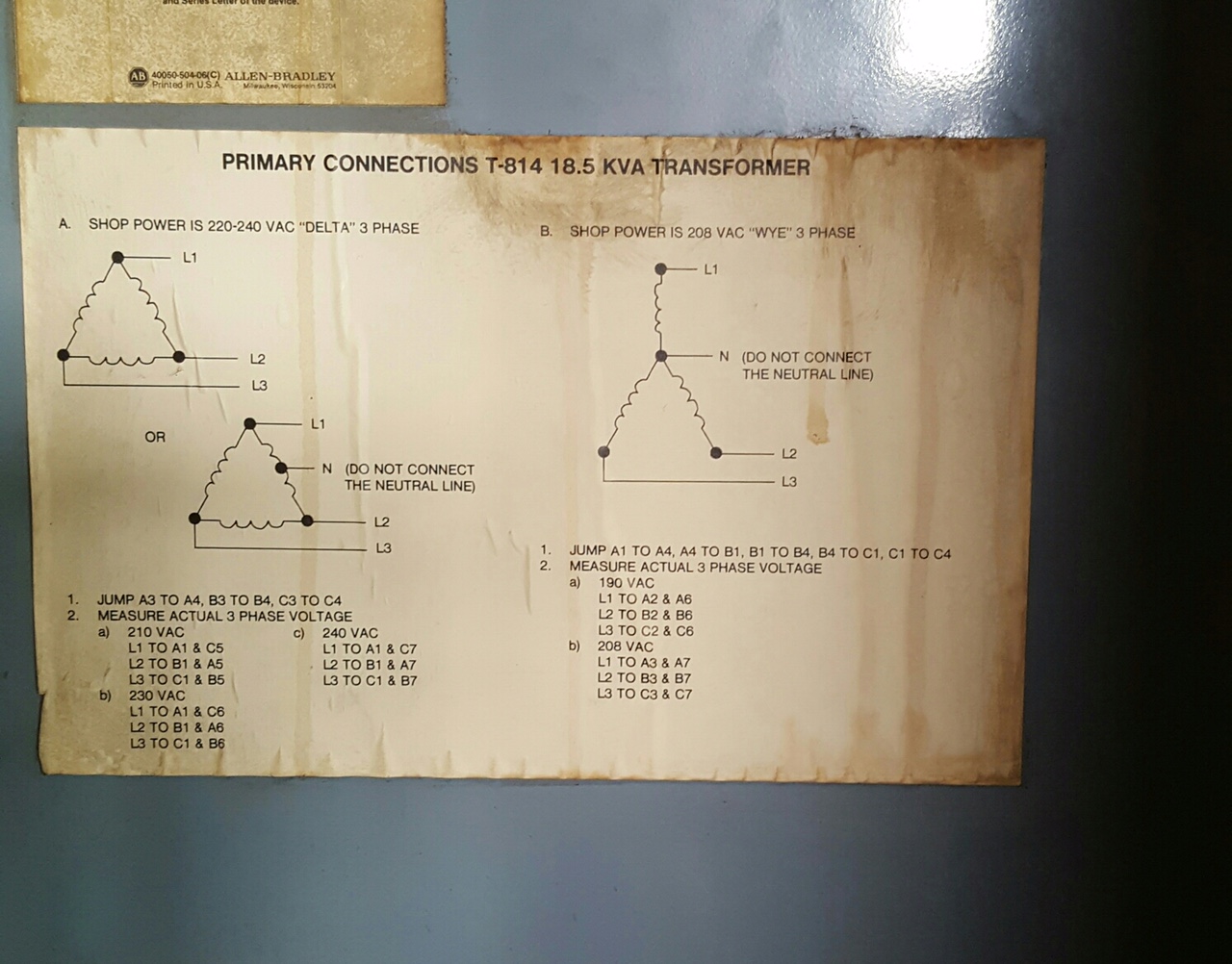

Now there is some confusion on how to hook the machine up and there doesn't seem to be a whole lot of information about the transformer(s) online within the machine. We are a little timid to just hook it up to 220 household and see what happens. Do anyone believe this would be an issue? Is there a way to change the jumper settings so it will able to utilize 220v single phase based on the attached images? I am a mechanical guy and not very good with electrical transformer understanding. I mean, the diagram states 210v & 230v, but three phase? Ive never heard of 210 or 230 3 phase.

Ive heard of 3 phase inverters and such but we are trying to get out of this without burning anymore cash.

I hope someone here can help. Thanks.

A friend of mine just purchased a Fadal CNC machine and put it in his garage. Thinking that the electrical hookup would not be a big deal from three phase 208v to household single phase 220v, it was too good of a machine to pass on so it was purchased.

Now there is some confusion on how to hook the machine up and there doesn't seem to be a whole lot of information about the transformer(s) online within the machine. We are a little timid to just hook it up to 220 household and see what happens. Do anyone believe this would be an issue? Is there a way to change the jumper settings so it will able to utilize 220v single phase based on the attached images? I am a mechanical guy and not very good with electrical transformer understanding. I mean, the diagram states 210v & 230v, but three phase? Ive never heard of 210 or 230 3 phase.

Ive heard of 3 phase inverters and such but we are trying to get out of this without burning anymore cash.

I hope someone here can help. Thanks.