Hi guys I am in the process of making a constant current/constant voltage power supply controlled by a STM32F4 with a colour LCD touch screen.

I have already designed and made the control board and most other parts of the power supply and now I'm in the process of designing the high current output circuit. I am more of a digital person rather than analog and this is where I require the expertise of people smarter than I

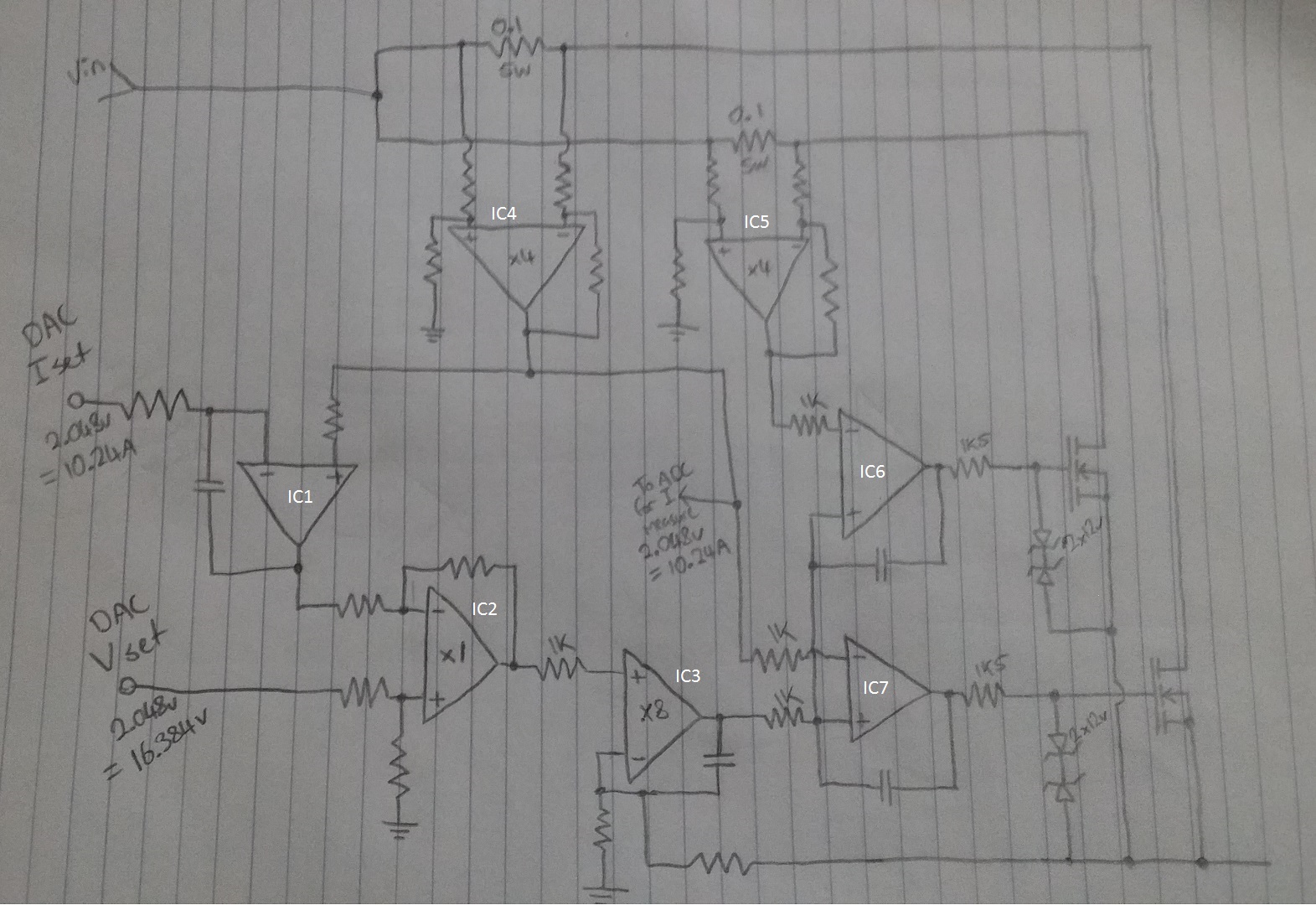

Attached is what I have designed however due to my limited experience with analog electronics I don't know if this is a good way to do it. As far as I know I may have broken several cardinal sins and not even know it, however I am pretty sure it will work (to a degree).

I apologise for the 'old fashioned' schematic but we work with what we have

I forgot to write it on the schematic but the output is in the lower right of picture (obviously). In the final unit there will be 2 of these in parallel for 20A output. The current sharing between each will be done in software.

The gains will all be set manually (calibrated) with 25 turn trimpots, this is why I haven't added resistor values.

The DAC's are 12 bit (MCP4922) and have a precision, low noise 2.048v reference. The op-amps (AD822AN) are rail-to-rail but will likely be run from a -5v/+25v rails. The output MOSFETs are Exicon 10N20.

Please make any suggestions you can think of and if you need any more information please ask.

I have already designed and made the control board and most other parts of the power supply and now I'm in the process of designing the high current output circuit. I am more of a digital person rather than analog and this is where I require the expertise of people smarter than I

Attached is what I have designed however due to my limited experience with analog electronics I don't know if this is a good way to do it. As far as I know I may have broken several cardinal sins and not even know it, however I am pretty sure it will work (to a degree).

I apologise for the 'old fashioned' schematic but we work with what we have

I forgot to write it on the schematic but the output is in the lower right of picture (obviously). In the final unit there will be 2 of these in parallel for 20A output. The current sharing between each will be done in software.

The gains will all be set manually (calibrated) with 25 turn trimpots, this is why I haven't added resistor values.

The DAC's are 12 bit (MCP4922) and have a precision, low noise 2.048v reference. The op-amps (AD822AN) are rail-to-rail but will likely be run from a -5v/+25v rails. The output MOSFETs are Exicon 10N20.

Please make any suggestions you can think of and if you need any more information please ask.

Last edited: