ThomsCircuit

Well-Known Member

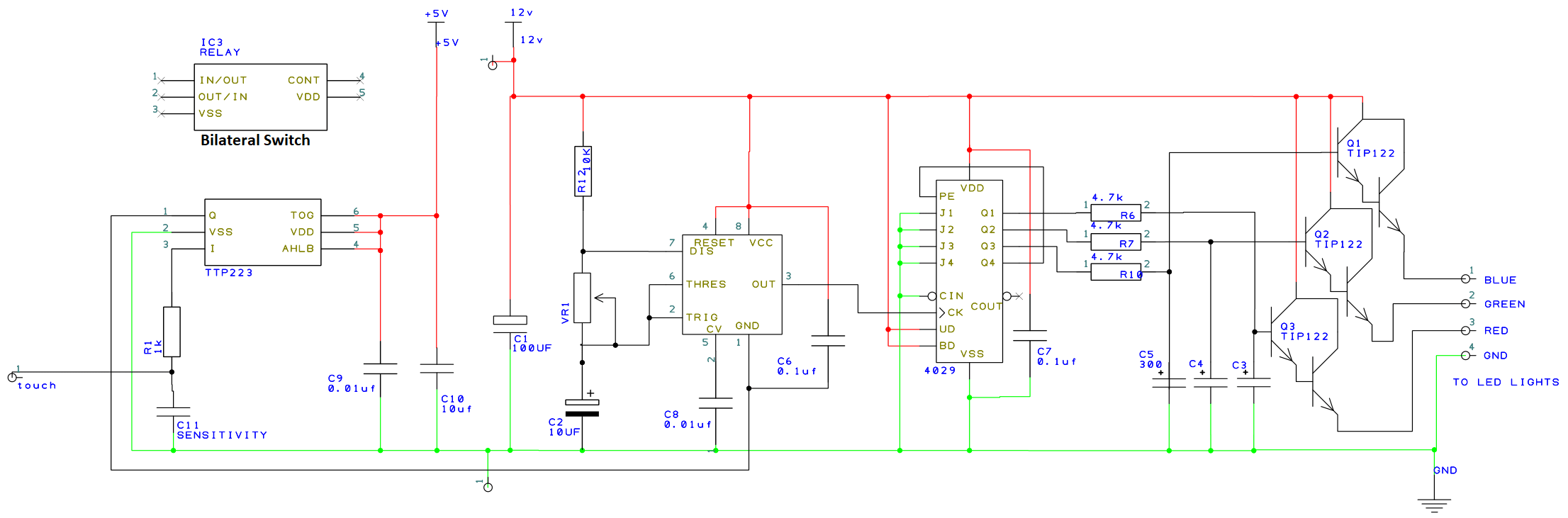

Id like to incorporate a touch switch into this circuit. i planned using the output from a TTP to a TC4S66F then the output from that to the GND of the 555. There may be a chance that i can skip the TC4 and use the low lock output from the TTP straight to the GND of the 555. if that is not the best solution then could you help me configure the TC4 to turn on the 555 via the output of the TTP like i originally planned?

TTP & TC4 5 volts

Rest of circuit 12 volts

TTP & TC4 5 volts

Rest of circuit 12 volts