Dr_Doggy

Well-Known Member

ok, so i started this since i need to control the esc of a bldc motor (for a RC plane) , after reading up I believe i need a 1ms pulse with a 20 ms delay, then a 1.5ms pulse with a 20ms delay, then a 2ms pulse with a 20ms delay, then i need it to repeat, maybe im wrong about this?? , maybe i only need single pulse width for specific rpm??

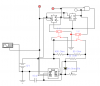

so i decided to rely on the 555 timer, in order to sequence the pulse i'v used some gates and an AND to reset it back to the first pulse width... now the simulation works great but i had to use a VOLTAGE CONTROLLED SWITCH, since i couldn't get the relay or transistors to work,..

so my other question is: is there such thing as a voltage controlled switch, what are their proper names>??

How would i replace the voltage switch with a transistor>?

also what could i do to substitute the AND gate,(i would like to avoid a using whole ic if I can)

even if this is wrong about the pulses id still like to use this configuration since I could use it as an IR encoder....?

so i decided to rely on the 555 timer, in order to sequence the pulse i'v used some gates and an AND to reset it back to the first pulse width... now the simulation works great but i had to use a VOLTAGE CONTROLLED SWITCH, since i couldn't get the relay or transistors to work,..

so my other question is: is there such thing as a voltage controlled switch, what are their proper names>??

How would i replace the voltage switch with a transistor>?

also what could i do to substitute the AND gate,(i would like to avoid a using whole ic if I can)

even if this is wrong about the pulses id still like to use this configuration since I could use it as an IR encoder....?