Hi all, looking for advice on an "annoyance" issue with my vehicle's AC controls.

A while back, the blower motor in my 2001 Chevrolet Blazer (S10) siezed up, of course blowing a fuse.

Replacing the blasted thing was a pain, but I managed to do it no problem. Of course, having been in a shorted condition the wires and connections got hot throughout the circuit.

This vehicle has 205,000 miles on the engine and transmission and still runs well, so it is paying dividends for me to keep it going, but I don't like investing too much money in it. When the engine or transmission goes, so will the Blazer.

Anyhow, not long after replacing the blower the relay failed. At first I thought it might be the resistor network under the hood, and simply replaced that. The failure occured one blower speed at a time, starting with high. But replacing the resistors did no good. So I got a new relay.

Bingo, problem fixed, for a while. After a few weeks the high speed went out again, then not long after that the other speeds went. The relay was a cheap aftermarket, but for convenience sake I bought another one and went to replace it. I found when taking a closer look that the female terminals in the connecting cable were burnt, probably from overheating when the original motor failed and I hadn't noticed.

I'm kind of lazy and figured I'd just try scraping the contacts, squeezing them with pliars for a snugger connection, and go. So I did, and replaced the relay again.

Well, it took longer, but eventually that relay quit working too.

So now I'm at the point where I'm not going to waste money on more relays and want a cheap, easy solution. So I have an idea.

I happened to save the last relay, and today I broke into it to have a look. After checking it with an ohm meter, it doesn't appear damaged...well, I take that back, I suspect the coil. It is made of very thin wire.

It ohmed out at 90 Ohms. It has a parallel resistor (blue, grey,brown=680 ohms) I'm not sure what the coil should read, but typically I would expect near shorted. So perhaps the coil is what keeps going bad.

The contacts seem clean and pass continuity when manually pushed closed or in the NC state.

I'm thinking there is a high resistance somewhere at a connection point that is keeping this relay from working properly.

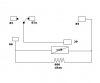

As I said, this is an old vehicle, not worth putting money into, so here is my idea. Instead of buying a new wiring harness for the relay, I'm thinking I'll just clip the common wire and the wire for the contact that energizes the fan when the closure occurs. I'm assuming that would NOT be the NC contact, but the other one. Basically bypassing the relay and having the fan run full speed all the time. Actually, the fan only runs when the AC switch or heater is on anyway, so I'm only giving up the variability.

I'm thinking to solder or crimp contact point#87 and #30 on the wiring harness and just remove the relay from the circuit (to prevent problems if someone moved the speed switch).

I don't have a wiring diagram and don't know what might "bite me" if I did such a thing. Anyone have experience with this?

A while back, the blower motor in my 2001 Chevrolet Blazer (S10) siezed up, of course blowing a fuse.

Replacing the blasted thing was a pain, but I managed to do it no problem. Of course, having been in a shorted condition the wires and connections got hot throughout the circuit.

This vehicle has 205,000 miles on the engine and transmission and still runs well, so it is paying dividends for me to keep it going, but I don't like investing too much money in it. When the engine or transmission goes, so will the Blazer.

Anyhow, not long after replacing the blower the relay failed. At first I thought it might be the resistor network under the hood, and simply replaced that. The failure occured one blower speed at a time, starting with high. But replacing the resistors did no good. So I got a new relay.

Bingo, problem fixed, for a while. After a few weeks the high speed went out again, then not long after that the other speeds went. The relay was a cheap aftermarket, but for convenience sake I bought another one and went to replace it. I found when taking a closer look that the female terminals in the connecting cable were burnt, probably from overheating when the original motor failed and I hadn't noticed.

I'm kind of lazy and figured I'd just try scraping the contacts, squeezing them with pliars for a snugger connection, and go. So I did, and replaced the relay again.

Well, it took longer, but eventually that relay quit working too.

So now I'm at the point where I'm not going to waste money on more relays and want a cheap, easy solution. So I have an idea.

I happened to save the last relay, and today I broke into it to have a look. After checking it with an ohm meter, it doesn't appear damaged...well, I take that back, I suspect the coil. It is made of very thin wire.

It ohmed out at 90 Ohms. It has a parallel resistor (blue, grey,brown=680 ohms) I'm not sure what the coil should read, but typically I would expect near shorted. So perhaps the coil is what keeps going bad.

The contacts seem clean and pass continuity when manually pushed closed or in the NC state.

I'm thinking there is a high resistance somewhere at a connection point that is keeping this relay from working properly.

As I said, this is an old vehicle, not worth putting money into, so here is my idea. Instead of buying a new wiring harness for the relay, I'm thinking I'll just clip the common wire and the wire for the contact that energizes the fan when the closure occurs. I'm assuming that would NOT be the NC contact, but the other one. Basically bypassing the relay and having the fan run full speed all the time. Actually, the fan only runs when the AC switch or heater is on anyway, so I'm only giving up the variability.

I'm thinking to solder or crimp contact point#87 and #30 on the wiring harness and just remove the relay from the circuit (to prevent problems if someone moved the speed switch).

I don't have a wiring diagram and don't know what might "bite me" if I did such a thing. Anyone have experience with this?