Hi,

I got about 10 of these very cheaply a while back, along with some P-channel mosfets in the hope to make some *relatively* simple buck converters. I realise there is the MC34063A, as well as national's 'simple switchers', but I have these and want to get them working for me

Essentially, I'm after a small footprint replacement for a standard LM7805 linear regulator for medium current applications. The 7805 is the first port of call but when one draws over 150-200mA, with a 12V supply, one quickly requires a heatsink, which takes up space, and I never like anything on my PCB's to get hot An LDO would be great but this is mainly for development boards, and I don't want to restrict the power supply to <8V input.

An LDO would be great but this is mainly for development boards, and I don't want to restrict the power supply to <8V input.

So, LM3845, 5V out. With Vin from say 8-16V which should cover 9,12 and 15V adapters. A current output of 500mA should be possible but it'll probably be running at 100-200mA nominal.

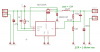

I prototyped the circuit in the datasheet, making sure all my parts were equivilents, with the same value, and similar, if not higher ratings in current/voltage. It is designed to output 3.3V @ 500mA max from 12V. Although the evaluation board applicaiton note (same circuit) claims it will hold regulation for 8-30V input. - According to my setup, this ain't true, so I'm obviously doing something wrong. When using a 10v supply the output drop's at around 100mA, by 200mA, the 3.3v output drops to 2.7.

When changing the feedback resistors for 5v output, it just about manages to hold regulation to 480mA, which is great, but my P-channel mosfet gets HOT. Specs here:

https://www.electro-tech-online.com/custompdfs/2010/08/ND2FNDT456P.pdf

Everything else in the circuit is the same, except the shottky diode is rated for 3A, rather than 1A.

I understand that we're talking, say 80% efficiency here, so with 5v @ 0.5A out, 2.5W , the input being 2.5/0.8 = 3.125, the entire converter must disapate 0.625W (between the switch, diode, IC and inductor). But I'm guessing my efficiency is far lower.

Any example circuits apart from those from national? Seems they removed this device from their 'workbench' software, and no SPICE models are available

I got about 10 of these very cheaply a while back, along with some P-channel mosfets in the hope to make some *relatively* simple buck converters. I realise there is the MC34063A, as well as national's 'simple switchers', but I have these and want to get them working for me

Essentially, I'm after a small footprint replacement for a standard LM7805 linear regulator for medium current applications. The 7805 is the first port of call but when one draws over 150-200mA, with a 12V supply, one quickly requires a heatsink, which takes up space, and I never like anything on my PCB's to get hot

So, LM3845, 5V out. With Vin from say 8-16V which should cover 9,12 and 15V adapters. A current output of 500mA should be possible but it'll probably be running at 100-200mA nominal.

I prototyped the circuit in the datasheet, making sure all my parts were equivilents, with the same value, and similar, if not higher ratings in current/voltage. It is designed to output 3.3V @ 500mA max from 12V. Although the evaluation board applicaiton note (same circuit) claims it will hold regulation for 8-30V input. - According to my setup, this ain't true, so I'm obviously doing something wrong. When using a 10v supply the output drop's at around 100mA, by 200mA, the 3.3v output drops to 2.7.

When changing the feedback resistors for 5v output, it just about manages to hold regulation to 480mA, which is great, but my P-channel mosfet gets HOT. Specs here:

https://www.electro-tech-online.com/custompdfs/2010/08/ND2FNDT456P.pdf

Everything else in the circuit is the same, except the shottky diode is rated for 3A, rather than 1A.

I understand that we're talking, say 80% efficiency here, so with 5v @ 0.5A out, 2.5W , the input being 2.5/0.8 = 3.125, the entire converter must disapate 0.625W (between the switch, diode, IC and inductor). But I'm guessing my efficiency is far lower.

Any example circuits apart from those from national? Seems they removed this device from their 'workbench' software, and no SPICE models are available